CHM-HtDT

Pretank

SUS304/SUS316L

500L-30,000L

| Availability: | |

|---|---|

| Product Specification

Pretank double jacket stainless steel chemical reactor are ideal products designed specifically for the glue industry. Made of high-quality stainless steel material to ensure the product has excellent durability and hygienic standards. And it has advanced stirring design and efficient heating system to ensure that the glue materials can be fully mixed and reacted, improving production efficiency. Its safety valve and temperature control system ensure the safety and stability of the operating process.

We offer a variety of capacity options to meet different customer production needs. Whether it is small-scale or large-scale production, we can provide you with customized solutions

| Technical Parameters

-Design volume: 50L~50000L (The volume can be designed as required.)

-Reaction temperature: normal temperature -300℃ or higher, depending on working conditions.

-Reaction pressure: -0.1-0.1mpa.

-Equipment material: 304 stainless steel, 321 stainless steel, 316L stainless steel or other materials.

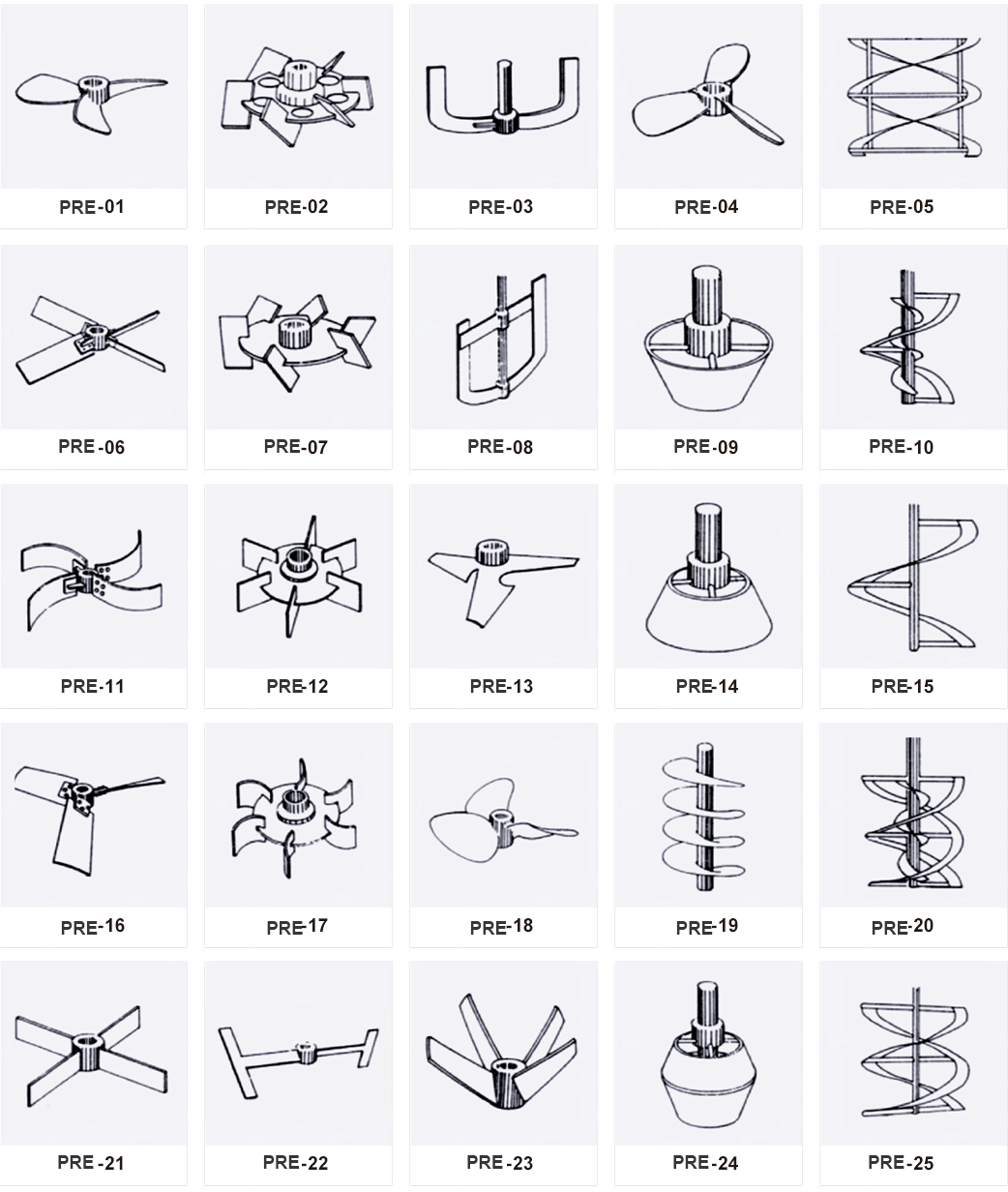

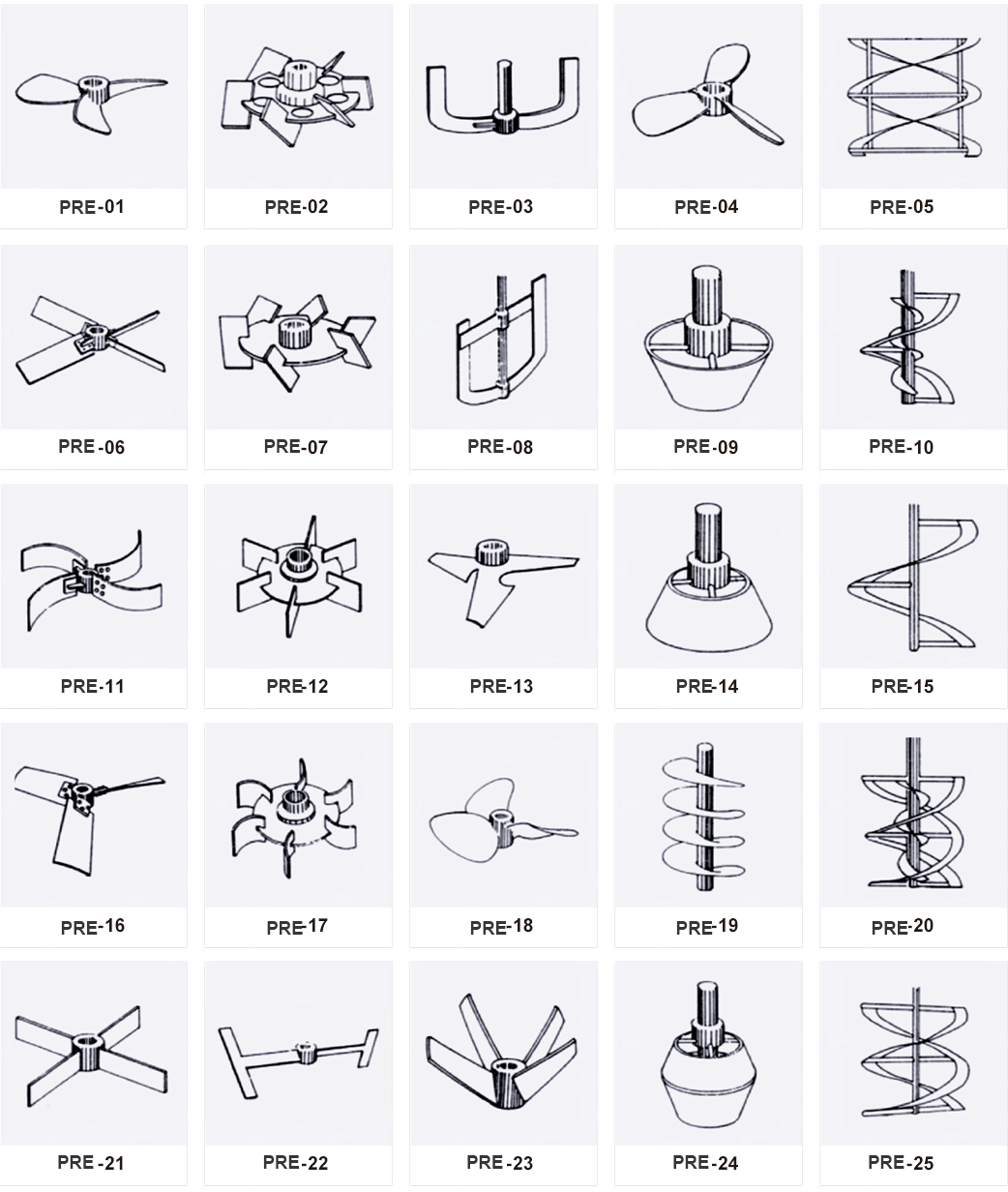

-Mixing form: paddle type, anchor paddle type, frame type, ribbon type, turbine type, dispersing disk type, combined type, etc.

-Heating method: electric heating, steam heating, water bath heating, thermal oil heating.

-Thermal medium: thermal oil, steam, hot water, electric heating.

-Heat transfer structure: jacket type, outer half-pipe type, inner coil type.

-Stirring speed: The choice of stirring speed depends on the mixing and mixing needs of the materials; for conventional liquid material polymerization, the speed is 63-85r/min; when mixing powder-containing materials with liquids, the dispersion effect needs to be achieved, and the speed is 0-1460r/min. ; Containing oil and liquid or two incompatible liquids need to be mixed to achieve an emulsification effect, and the rotation speed is 0-2800 r/min.

Please inquire particular If you need any of them.

| Mixer selection

| Features

Corrosion resistance: The stainless steel chemical reactor is made of materials with excellent corrosion resistance, such as stainless steel, which can resist chemical substances and corrosive solvents in the glue, ensuring the quality and stability of the product.

Efficient mixing: The reactor is equipped with an efficient stirring system, which can fully mix the glue raw materials to ensure uniform distribution of ingredients, thereby improving the quality and performance of the glue.

Temperature control: In the glue production process, temperature is one of the key factors. The reactor is equipped with a precise temperature control system, which can monitor and regulate the temperature in the reactor in real time to ensure that the glue reacts within the ideal temperature range.

Safety: Reactors in the glue industry are usually equipped with safety valves and emergency shutdown devices to ensure that timely measures can be taken in the event of abnormal situations to ensure the safety of operators.

Easy to clean and maintain: The design of the glue reactor takes into account the convenience of cleaning and maintenance. The internal surface is smooth and the easy-to-clean structure reduces residues and reduces the difficulty and time cost of cleaning and maintenance.

Customizable capacity: According to the scale and demand of glue production, the capacity of the reactor can be customized to meet the requirements of different scales of production.

| Comment&FAQ

1. Except for SUS304 material, what other material do you do for the vessels?

A: We can provide a variety of grades of stainless steel, including SUS316L,SUS321,SUS316Ti; We also can make with material of titanium and Hastelloy Alloy.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3.How do you ship the goods?

Goods are usually shipped in containers or flat rack with metal walls to protect them against extreme temperatures and bad weather conditions.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5.What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

| Certificate

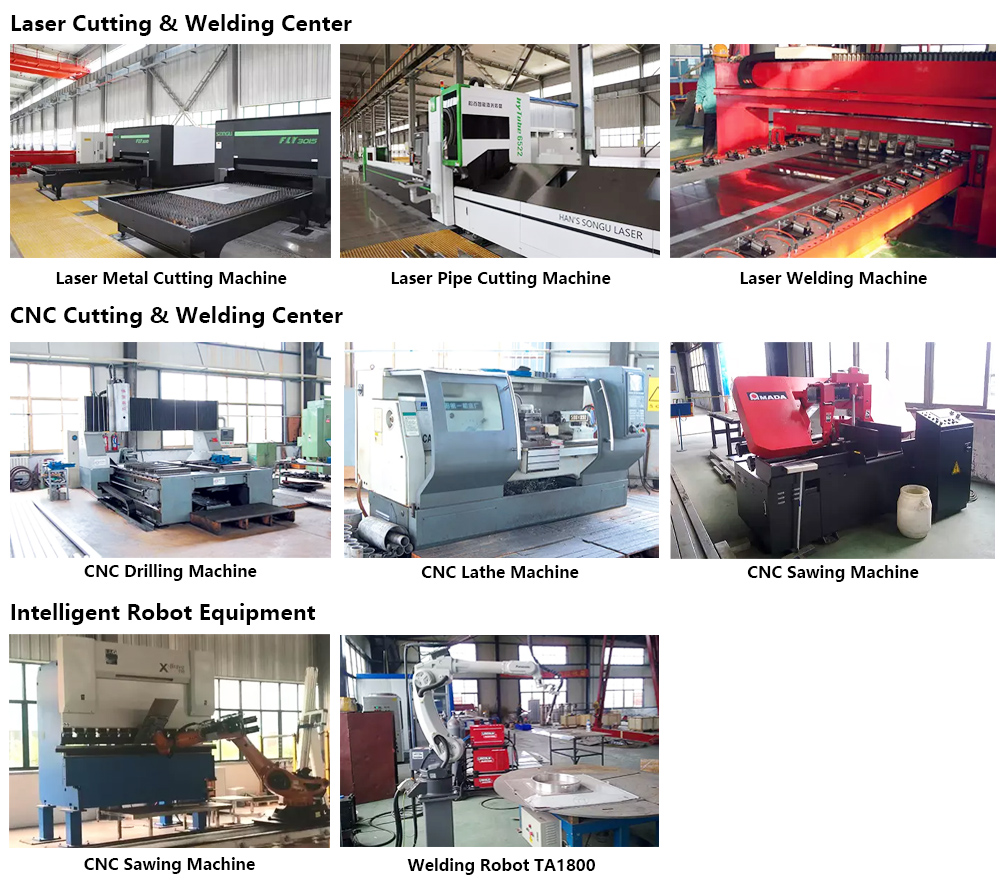

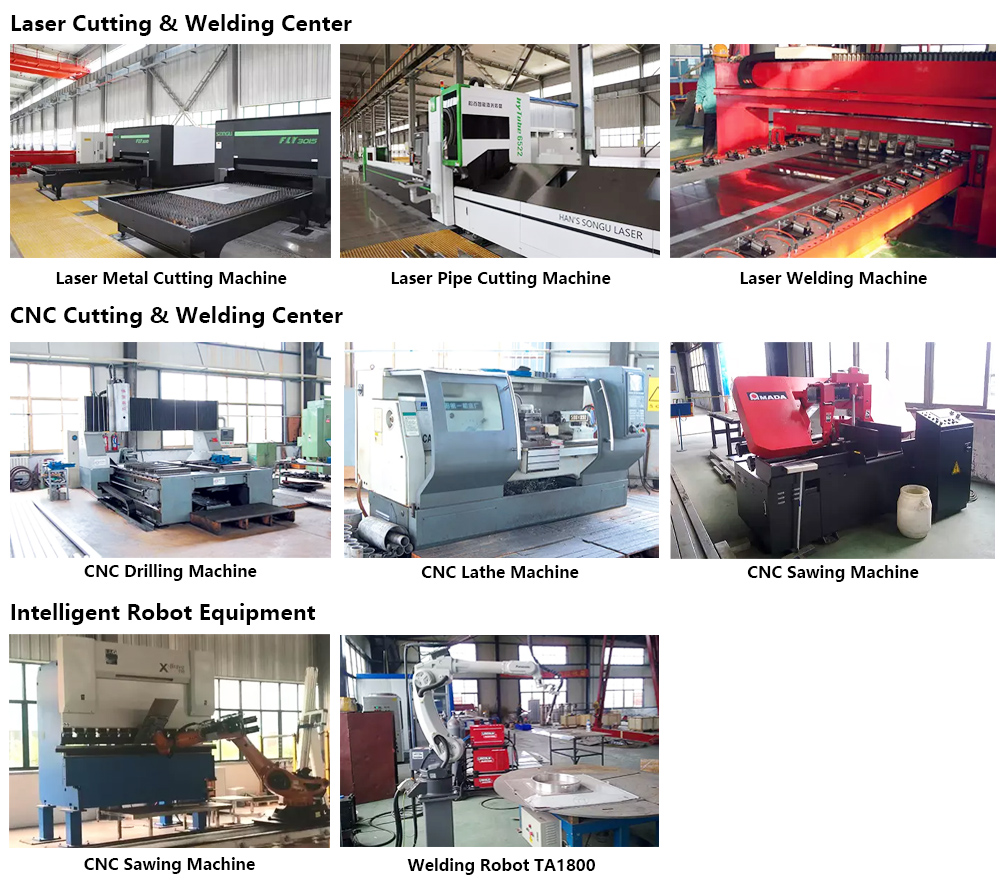

| Processing Machinery

Pretank employs cutting-edge manufacturing technology to craft our stainless steel tanks. Our state-of-the-art facilities feature automated processes such as auto Robotic welding machines, laser cutting/welding machines, CNC lathes, plasma cutting, and automatic welding machines.

These advanced machines not only eliminate manual labor but also significantly reduce the likelihood of human errors and defects in the tanks. By leveraging automation, we enhance the overall quality of our tanks and streamline the construction process. This not only ensures a higher standard of craftsmanship but also accelerates the construction timeline, offering efficient and top-notch solutions to our clients.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

| Product Specification

Pretank double jacket stainless steel chemical reactor are ideal products designed specifically for the glue industry. Made of high-quality stainless steel material to ensure the product has excellent durability and hygienic standards. And it has advanced stirring design and efficient heating system to ensure that the glue materials can be fully mixed and reacted, improving production efficiency. Its safety valve and temperature control system ensure the safety and stability of the operating process.

We offer a variety of capacity options to meet different customer production needs. Whether it is small-scale or large-scale production, we can provide you with customized solutions

| Technical Parameters

-Design volume: 50L~50000L (The volume can be designed as required.)

-Reaction temperature: normal temperature -300℃ or higher, depending on working conditions.

-Reaction pressure: -0.1-0.1mpa.

-Equipment material: 304 stainless steel, 321 stainless steel, 316L stainless steel or other materials.

-Mixing form: paddle type, anchor paddle type, frame type, ribbon type, turbine type, dispersing disk type, combined type, etc.

-Heating method: electric heating, steam heating, water bath heating, thermal oil heating.

-Thermal medium: thermal oil, steam, hot water, electric heating.

-Heat transfer structure: jacket type, outer half-pipe type, inner coil type.

-Stirring speed: The choice of stirring speed depends on the mixing and mixing needs of the materials; for conventional liquid material polymerization, the speed is 63-85r/min; when mixing powder-containing materials with liquids, the dispersion effect needs to be achieved, and the speed is 0-1460r/min. ; Containing oil and liquid or two incompatible liquids need to be mixed to achieve an emulsification effect, and the rotation speed is 0-2800 r/min.

Please inquire particular If you need any of them.

| Mixer selection

| Features

Corrosion resistance: The stainless steel chemical reactor is made of materials with excellent corrosion resistance, such as stainless steel, which can resist chemical substances and corrosive solvents in the glue, ensuring the quality and stability of the product.

Efficient mixing: The reactor is equipped with an efficient stirring system, which can fully mix the glue raw materials to ensure uniform distribution of ingredients, thereby improving the quality and performance of the glue.

Temperature control: In the glue production process, temperature is one of the key factors. The reactor is equipped with a precise temperature control system, which can monitor and regulate the temperature in the reactor in real time to ensure that the glue reacts within the ideal temperature range.

Safety: Reactors in the glue industry are usually equipped with safety valves and emergency shutdown devices to ensure that timely measures can be taken in the event of abnormal situations to ensure the safety of operators.

Easy to clean and maintain: The design of the glue reactor takes into account the convenience of cleaning and maintenance. The internal surface is smooth and the easy-to-clean structure reduces residues and reduces the difficulty and time cost of cleaning and maintenance.

Customizable capacity: According to the scale and demand of glue production, the capacity of the reactor can be customized to meet the requirements of different scales of production.

| Comment&FAQ

1. Except for SUS304 material, what other material do you do for the vessels?

A: We can provide a variety of grades of stainless steel, including SUS316L,SUS321,SUS316Ti; We also can make with material of titanium and Hastelloy Alloy.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3.How do you ship the goods?

Goods are usually shipped in containers or flat rack with metal walls to protect them against extreme temperatures and bad weather conditions.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5.What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

| Certificate

| Processing Machinery

Pretank employs cutting-edge manufacturing technology to craft our stainless steel tanks. Our state-of-the-art facilities feature automated processes such as auto Robotic welding machines, laser cutting/welding machines, CNC lathes, plasma cutting, and automatic welding machines.

These advanced machines not only eliminate manual labor but also significantly reduce the likelihood of human errors and defects in the tanks. By leveraging automation, we enhance the overall quality of our tanks and streamline the construction process. This not only ensures a higher standard of craftsmanship but also accelerates the construction timeline, offering efficient and top-notch solutions to our clients.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

content is empty!