ET

Pretank

SUS304/SUS316L

1000L to 100,000L, can be customized

| Availability: | |

|---|---|

| Product Description

Our tank is engineered to optimize enzymatic hydrolysis, a pivotal stage in vinegar production where enzymes break down raw materials into fermentable sugars. With carefully controlled conditions including temperature, pH, and agitation, our tank ensures maximal enzymatic activity, resulting in superior yields and flavor profiles.

| Features

Efficient Decomposition:

This tank excels in breaking down complex compounds like pectin and starch in juice through enzymolysis, resulting in the production of soluble small molecules.

Foam Reduction:

The Enzymolysis Tank significantly reduces foam during fermentation, ensuring a smoother and more controlled production process.

Precision Craftsmanship:

Meticulously crafted with precision and expertise, this tank guarantees optimal performance in vinegar production.

Streamlined Fermentation:

By effectively eliminating foam, the Enzymolysis Tank streamlines the fermentation process, facilitating seamless production and enhancing quality control.

Precision Control:

Equipped with state-of-the-art control systems, our Enzymolysis Tank offers precise regulation of critical parameters such as temperature, pH, and agitation speed. This level of control empowers vinegar producers to fine-tune the enzymatic process according to specific requirements, ensuring consistency and repeatability in every batch.

| Configurations

Material: Food grade SS304

Vertical, cone top & bottom, legs

Agitator, Top manholes, breathing apparatus, inlet and outlet pipe, level sensor, necessary nozzles and fittings

Choose our Enzymolysis Tank and witness the transformative impact it has on your vinegar production. Experience reduced foam, enhanced fermentation, and impeccable quality – all with the touch of professionalism that sets your business apart.

| Certificate

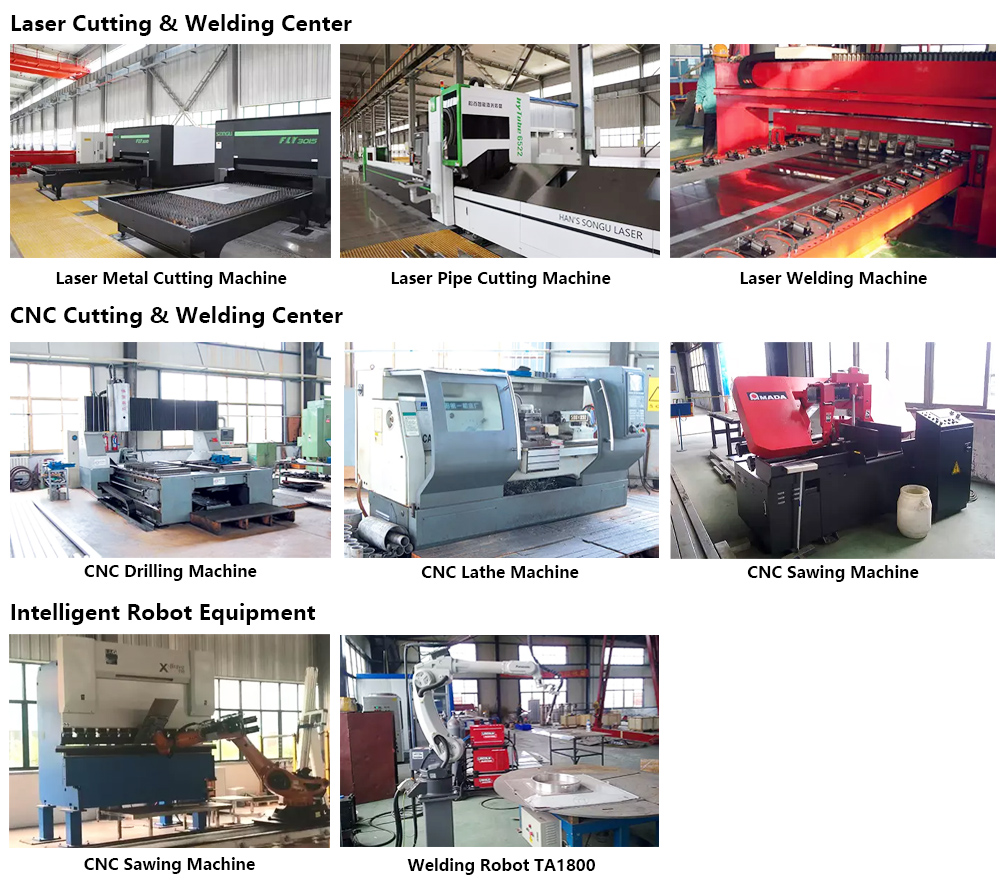

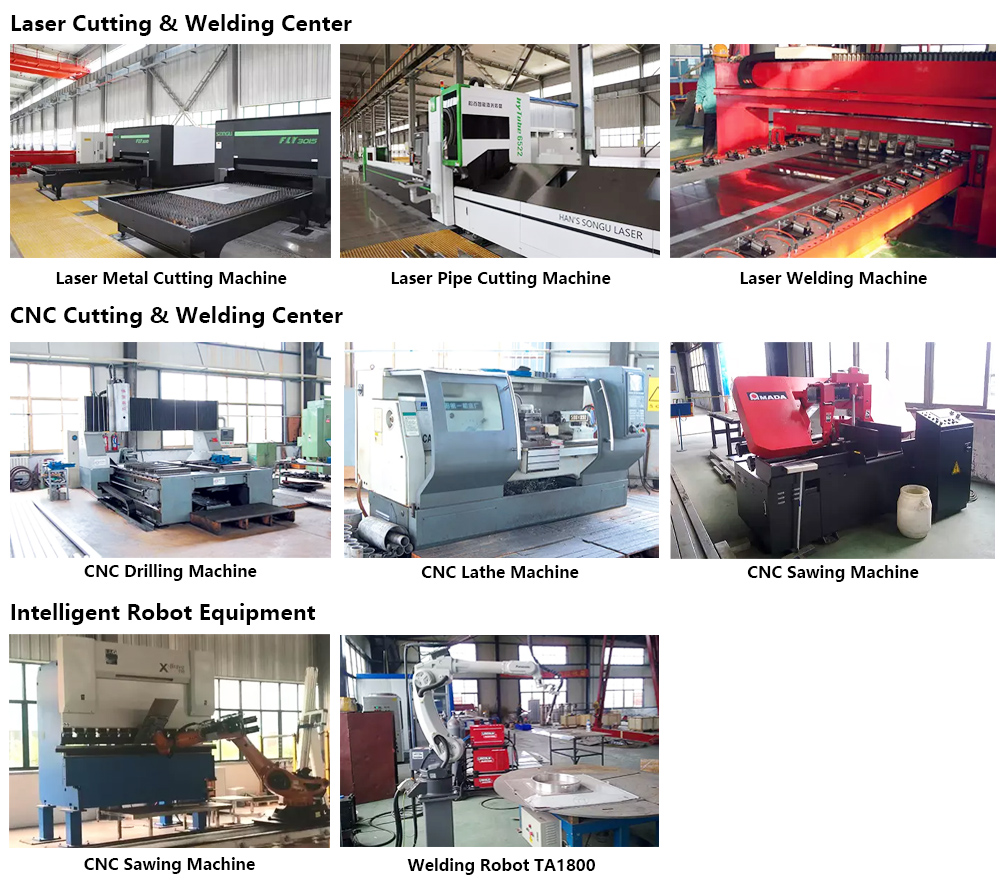

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Product Description

Our tank is engineered to optimize enzymatic hydrolysis, a pivotal stage in vinegar production where enzymes break down raw materials into fermentable sugars. With carefully controlled conditions including temperature, pH, and agitation, our tank ensures maximal enzymatic activity, resulting in superior yields and flavor profiles.

| Features

Efficient Decomposition:

This tank excels in breaking down complex compounds like pectin and starch in juice through enzymolysis, resulting in the production of soluble small molecules.

Foam Reduction:

The Enzymolysis Tank significantly reduces foam during fermentation, ensuring a smoother and more controlled production process.

Precision Craftsmanship:

Meticulously crafted with precision and expertise, this tank guarantees optimal performance in vinegar production.

Streamlined Fermentation:

By effectively eliminating foam, the Enzymolysis Tank streamlines the fermentation process, facilitating seamless production and enhancing quality control.

Precision Control:

Equipped with state-of-the-art control systems, our Enzymolysis Tank offers precise regulation of critical parameters such as temperature, pH, and agitation speed. This level of control empowers vinegar producers to fine-tune the enzymatic process according to specific requirements, ensuring consistency and repeatability in every batch.

| Configurations

Material: Food grade SS304

Vertical, cone top & bottom, legs

Agitator, Top manholes, breathing apparatus, inlet and outlet pipe, level sensor, necessary nozzles and fittings

Choose our Enzymolysis Tank and witness the transformative impact it has on your vinegar production. Experience reduced foam, enhanced fermentation, and impeccable quality – all with the touch of professionalism that sets your business apart.

| Certificate

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

content is empty!