AST

Pretank

SUS304/SUS316L

1000L to 100,000L, can be customized

| Availability: | |

|---|---|

| Product Description

Constructed from premium-grade stainless steel, our tanks offer unparalleled resistance to corrosion, ensuring the purity and integrity of your alcoholic beverages are maintained throughout the storage process. The smooth, non-reactive surface of stainless steel prevents any unwanted interactions with the liquid contents, preserving their flavor profiles and characteristics.

Equipped with advanced temperature control systems, our tanks provide precise management of fermentation and aging conditions, allowing for optimal maturation and flavor development. From aging fine wines to conditioning craft beers, our stainless steel storage tanks offer versatility and reliability, accommodating a wide range of beverage production processes.

With a range of sizes and configurations available, our tanks can be tailored to meet the specific needs of your operation, whether you're a small-batch artisanal producer or a large-scale commercial facility. Designed for ease of use and maintenance, they feature convenient access ports, sanitary fittings, and robust construction for long-term performance.

| Product Specification

Type | Capacity L | Shell dimension D(mm) | Total height H(mm) | Legs N |

ST-1 | 1000 | Φ920*1500 | 2180 | 3 |

ST-2 | 2000 | Φ1270*1610 | 2600 | 3 |

ST-3 | 3000 | Φ1500*1830 | 3000 | 4 |

ST-4 | 4000 | Φ1600*2000 | 3250 | 4 |

ST-5 | 5000 | Φ1600*2440 | 3650 | 4 |

ST-6 | 6000 | Φ1800*2440 | 3500 | 4 |

ST-8 | 8000 | Φ1820*3050 | 4650 | 4 |

ST-10 | 10,000 | Φ1900*3660 | 5050 | 4 |

ST-12 | 12,000 | Φ1900*4270 | 5750 | 4 |

ST-15 | 15,000 | Φ2000*4880 | 5950 | 4 |

ST-20 | 20,000 | Φ2300*4880 | 6100 | 4 |

ST-25 | 25,000 | Φ2600*4880 | 6050 | 4 |

ST-30 | 30,000 | Φ2600*5500 | 6550 | 4/6 |

Choose our Finished Alcohol Storage Tank and experience the difference in quality and performance. Elevate your fermentation processes to new heights with this exceptional storage solution.

| Features

Precision Craftsmanship and Durability:

Crafted with precision and built to last, the storage tank boasts robust construction for long-term reliability and efficient storage of finished alcohol.

Optimal Performance:

The tank's professional design ensures optimal performance, providing a reliable solution for storing finished alcohol while maintaining its quality.

Fermentation without Pulp:

Specifically engineered to facilitate fermentation without pulp, making it ideal for distilleries and breweries prioritizing purity and clarity in their final products.

Precise Control Over Fermentation:

Innovative design allows for precise control over the fermentation process, ensuring consistent results and high-quality alcohol production.

Flexibility in Production:

Offers flexibility by allowing storage of finished alcohol for extended periods without compromising quality, catering to various production needs and fluctuations in demand.

Safety and Hygiene:

Manufactured using food-grade materials compliant with industry standards, ensuring safety and hygiene to prevent contamination and maintain the integrity of the finished alcohol.

| Product Structure

- Cylindrical Shell

- Conical top

- Conical or slop flat bottom

- 4 legs with adjustable feet and levelling tubes

- Manhole, on the top or at side

- Levelling indicator

- Fire-proof Breathing valve

- Sampler

- Drainage outlet

- CIP arm and spray ball

- Lifting lugs & Ladder rack

- Jacket, Agitator, Insulation can be optional

| Customer References

| Certificate

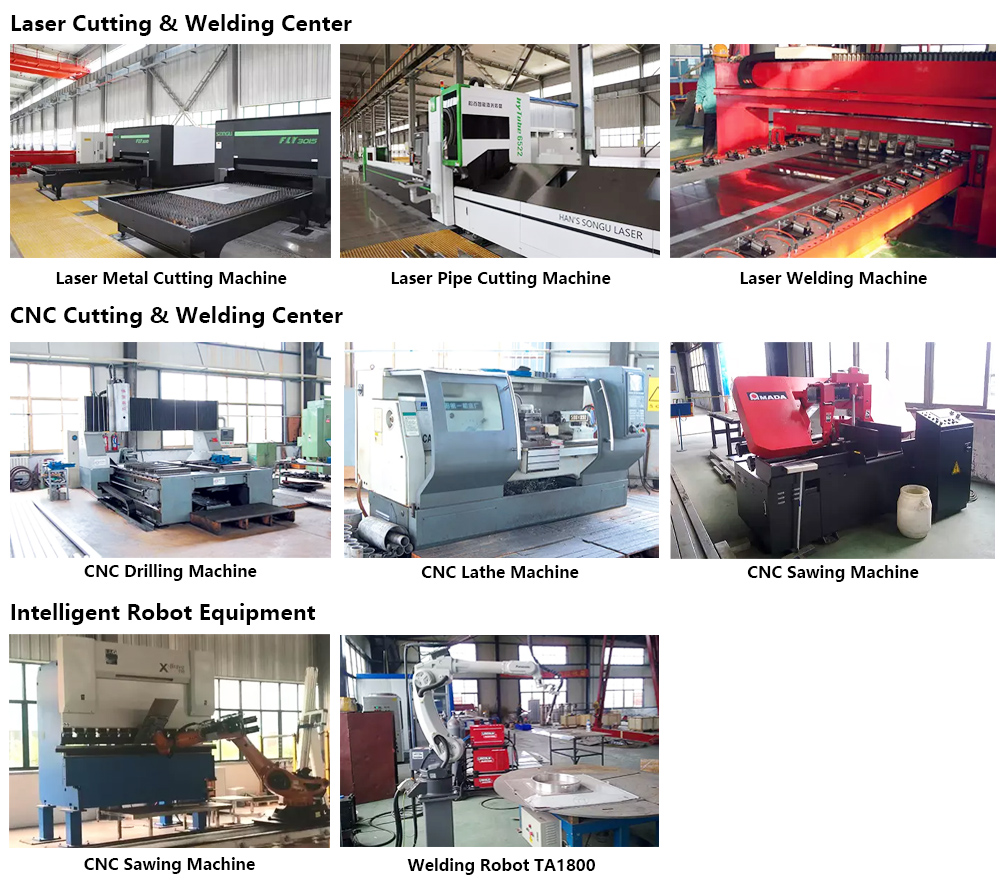

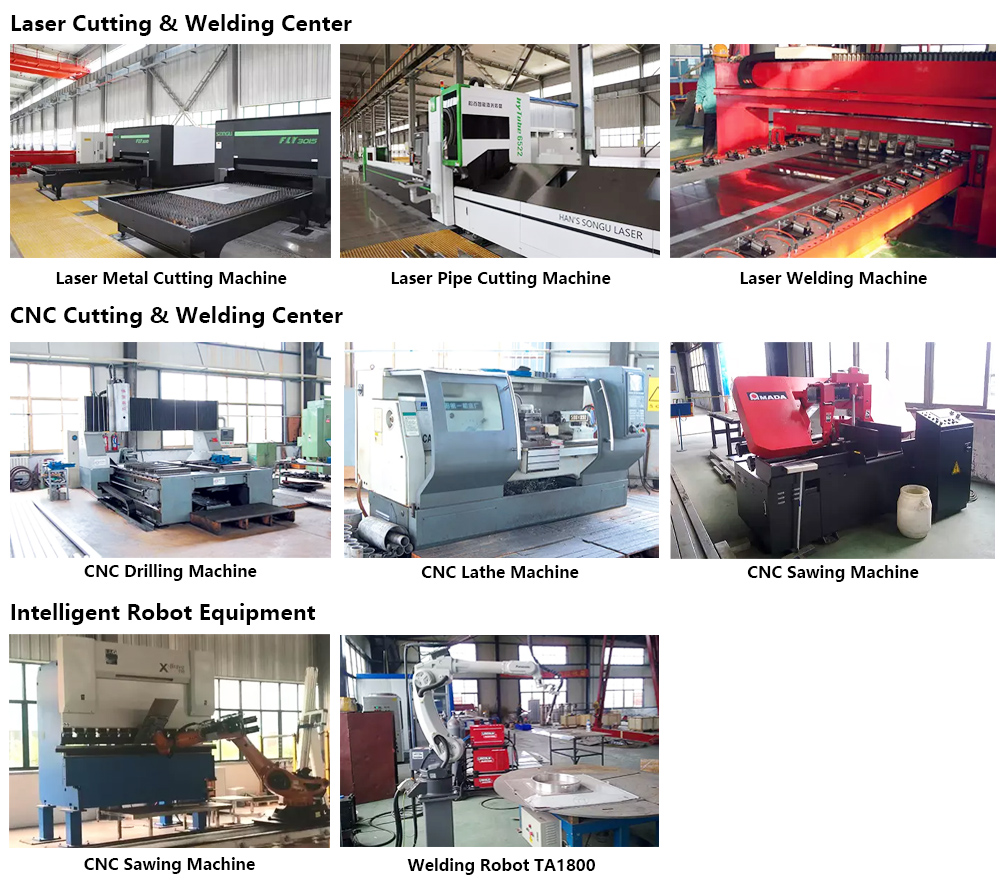

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Product Description

Constructed from premium-grade stainless steel, our tanks offer unparalleled resistance to corrosion, ensuring the purity and integrity of your alcoholic beverages are maintained throughout the storage process. The smooth, non-reactive surface of stainless steel prevents any unwanted interactions with the liquid contents, preserving their flavor profiles and characteristics.

Equipped with advanced temperature control systems, our tanks provide precise management of fermentation and aging conditions, allowing for optimal maturation and flavor development. From aging fine wines to conditioning craft beers, our stainless steel storage tanks offer versatility and reliability, accommodating a wide range of beverage production processes.

With a range of sizes and configurations available, our tanks can be tailored to meet the specific needs of your operation, whether you're a small-batch artisanal producer or a large-scale commercial facility. Designed for ease of use and maintenance, they feature convenient access ports, sanitary fittings, and robust construction for long-term performance.

| Product Specification

Type | Capacity L | Shell dimension D(mm) | Total height H(mm) | Legs N |

ST-1 | 1000 | Φ920*1500 | 2180 | 3 |

ST-2 | 2000 | Φ1270*1610 | 2600 | 3 |

ST-3 | 3000 | Φ1500*1830 | 3000 | 4 |

ST-4 | 4000 | Φ1600*2000 | 3250 | 4 |

ST-5 | 5000 | Φ1600*2440 | 3650 | 4 |

ST-6 | 6000 | Φ1800*2440 | 3500 | 4 |

ST-8 | 8000 | Φ1820*3050 | 4650 | 4 |

ST-10 | 10,000 | Φ1900*3660 | 5050 | 4 |

ST-12 | 12,000 | Φ1900*4270 | 5750 | 4 |

ST-15 | 15,000 | Φ2000*4880 | 5950 | 4 |

ST-20 | 20,000 | Φ2300*4880 | 6100 | 4 |

ST-25 | 25,000 | Φ2600*4880 | 6050 | 4 |

ST-30 | 30,000 | Φ2600*5500 | 6550 | 4/6 |

Choose our Finished Alcohol Storage Tank and experience the difference in quality and performance. Elevate your fermentation processes to new heights with this exceptional storage solution.

| Features

Precision Craftsmanship and Durability:

Crafted with precision and built to last, the storage tank boasts robust construction for long-term reliability and efficient storage of finished alcohol.

Optimal Performance:

The tank's professional design ensures optimal performance, providing a reliable solution for storing finished alcohol while maintaining its quality.

Fermentation without Pulp:

Specifically engineered to facilitate fermentation without pulp, making it ideal for distilleries and breweries prioritizing purity and clarity in their final products.

Precise Control Over Fermentation:

Innovative design allows for precise control over the fermentation process, ensuring consistent results and high-quality alcohol production.

Flexibility in Production:

Offers flexibility by allowing storage of finished alcohol for extended periods without compromising quality, catering to various production needs and fluctuations in demand.

Safety and Hygiene:

Manufactured using food-grade materials compliant with industry standards, ensuring safety and hygiene to prevent contamination and maintain the integrity of the finished alcohol.

| Product Structure

- Cylindrical Shell

- Conical top

- Conical or slop flat bottom

- 4 legs with adjustable feet and levelling tubes

- Manhole, on the top or at side

- Levelling indicator

- Fire-proof Breathing valve

- Sampler

- Drainage outlet

- CIP arm and spray ball

- Lifting lugs & Ladder rack

- Jacket, Agitator, Insulation can be optional

| Customer References

| Certificate

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

content is empty!