CHM-Top2

Pretank

SUS304/SUS316L

500L-30,000L

| Availability: | |

|---|---|

| Product description

Our SS304 Double Jacket Stainless Steel Mixer Tank is a high-performance mixing solution designed for the painting industry. Made from premium-grade SUS304 or SUS316 stainless steel,with high polishing treatment, can meet the requirements of the daily chemical industry. It offers excellent corrosion resistance and durability.

Equipped with a jacket, the jacket can be used for heating to help mix various materials evenly.

The double jacket structure provides outstanding temperature control, allowing you to heat or cool according to your process requirements.

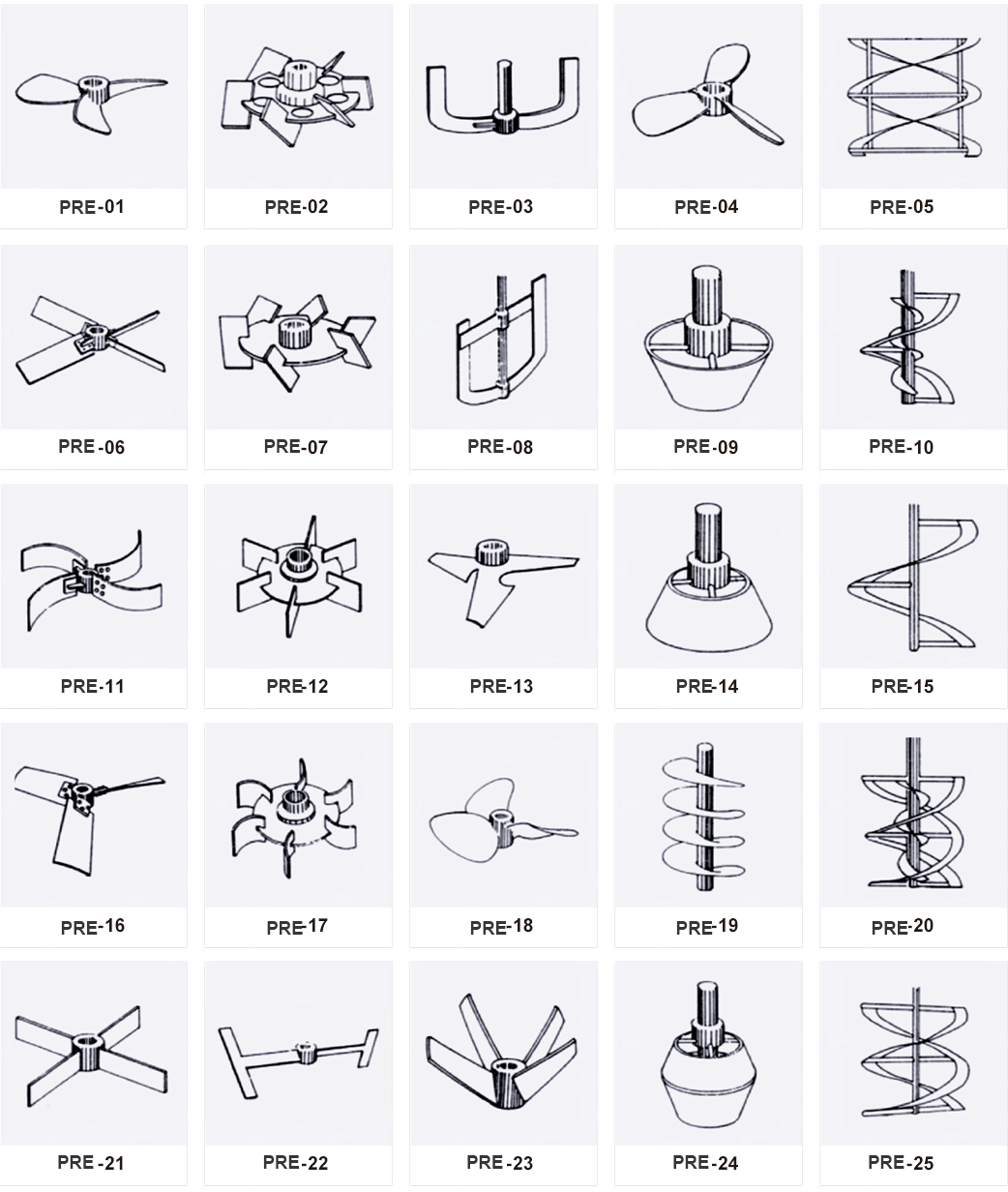

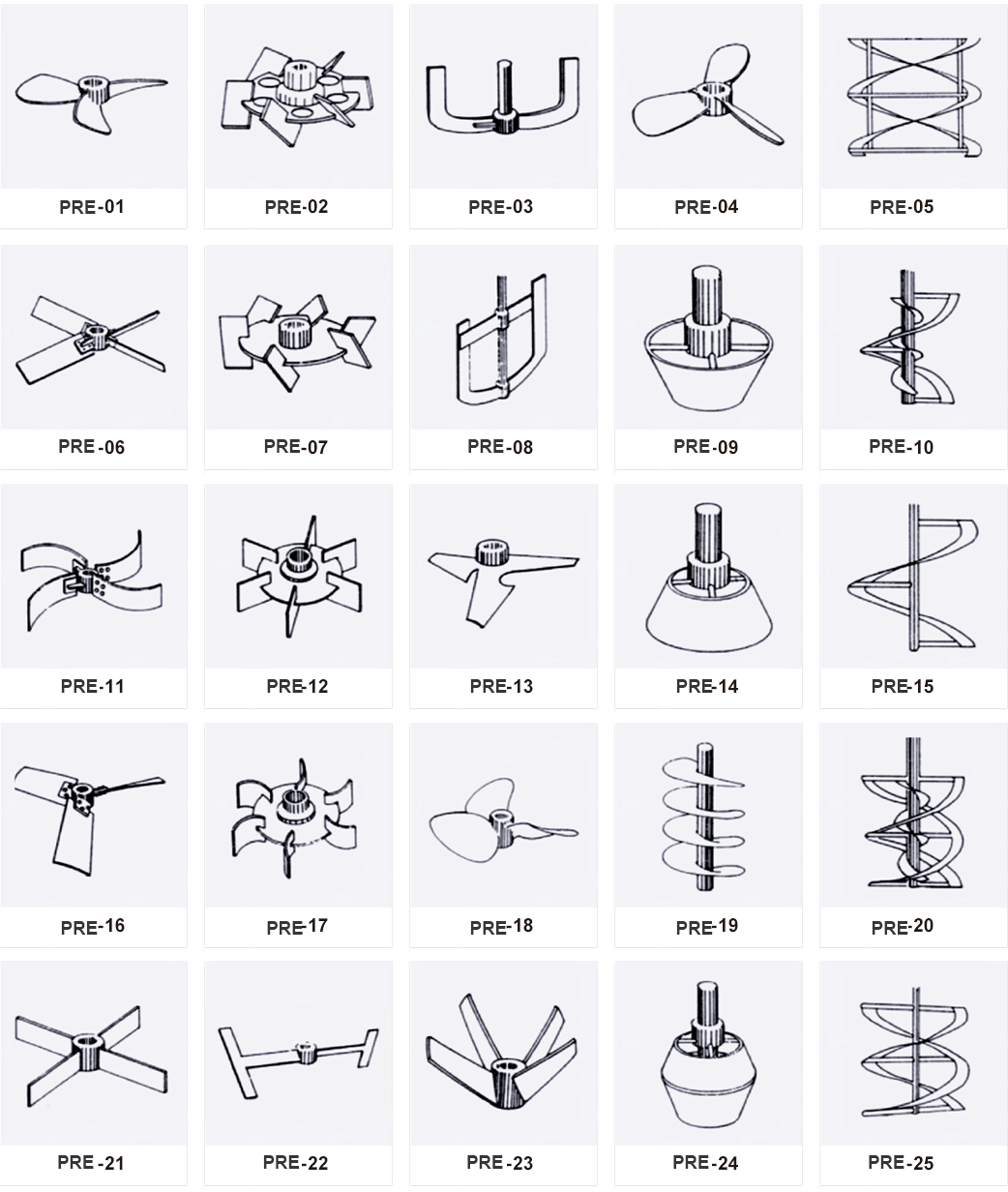

The mixing system can be configured with various blade types to ensure uniform stirring and efficient mixing.

Normal pressure, negative pressure, and pressurized containers can be customized according to customer needs.

Additionally, optional accessories such as electric lifts, turning mechanisms, and temperature control systems can be incorporated to accommodate the specific requirements for different customers.

| Features

Corrosion resistance: Stainless steel tanks exhibit excellent corrosion resistance, ensuring the integrity of the coating materials and longevity of the equipment.

High temperature resistance: These tanks can withstand high temperatures during the mixing process, allowing for efficient and effective mixing of paint and coating materials.

Hygienic and easy to clean: Stainless steel tanks have a smooth surface that is easy to clean, promoting cleanliness and preventing contamination in the mixing process.

Optimal mixing performance: These tanks are designed with efficient mixing mechanisms, resulting in thorough and uniform blending of paint and coating materials.

Energy efficiency: Stainless steel mixing tanks are engineered to minimize energy consumption while maintaining excellent mixing performance, contributing to cost savings and environmental sustainability.

Customizable features: These tanks can be equipped with various accessories and features, such as temperature control systems, agitators, and sampling valves, allowing for tailored solutions to meet specific requirements in the paint and coating industry.The thickness of the container is customized according to customer requirements. In order to ensure safety, the thickness of the container is calculated to ensure the quality and economy of the product.

Safety guarantee: The equipment is equipped with multiple safety measures, such as overload protection and leakage protection, to ensure safety during operation.

High degree of automation: The laundry detergent mixing tank has automated functions, including automatic feeding, automatic stirring and automatic discharging, which can significantly reduce the cost of manual operations.

| Techincal parameters

| Materials | SUS304/SUS316L,Carbon Steel,Nickel Alloy,Titanium etc |

| Materials Viscosity | ≤500,000 cps,customized |

| Production Capacity | 500-3000L,customized |

| Voltage | 208/220/380/400/415/440 V, 3Phase 50/60hz |

| Certification | GMP,CE, UL,CSA,IECE,ATEX |

| Application Industry | Used for dispersing and mixing in industries such as paint, ink, adhesives, dyes, pesticides etc. |

| Temperature control | Adaptable heating/cooling methods including electric heating, steam heating or water cooling ensure customization to your requirment. |

| Drive mode | Electric drive, pneumatic drive, hydraulic drive, can be customized |

| Speed | High speed type, medium speed type, low speed type,can be customized |

| Sealed form | A variety of sealing forms are available to meet the design requirements of vacuum, normal pressure, low pressure, medium pressure and high pressure. |

| Surface treatment | PTFE coating, polyurethane coating, tungsten carbide coating, etc. |

- Stainless steel 304 construction ensures durability and corrosion resistance.

- The tank features a semi-open top with hinged lids for easy access and an oval bottom for efficient mixing.

- Both the interior and exterior of the tank are finished with a smooth 2B finish.

- Sturdy lug supports provide stability and support to the tank.

- The tank includes a half pipe heating jacket for efficient heating of the contents.

- A 1/2" sampling valve allows for easy sampling of the liquid.

- A liquid level indicator is included to monitor the level of the liquid inside the tank.

- The top agitator is equipped with a motor, gearbox, paddle agitator, rack, and mechanical seal for effective mixing.

-The tank has 2" inlet and outlet connections for convenient fluid transfer.

- A 2" drainage outlet enables easy emptying of the tank.

- A breather is installed to regulate air pressure inside the tank.

- Additional accessories, such as a control box, pump, load cell, and stainless steel pipelines, are provided for enhanced functionality.

The stainless mixer tank is offered in a versatile capacity range spanning from 500 liters to 50,000 liters, and we provide customizable options to cater to your specific needs. To obtain more detailed information, please submit an inquiry, and our team will be glad to assist you further.

| Mixer selection

| Product packing

Covered with a blanket to prevent a collision.

Covered with a blanket to prevent a collision.  Employing a wooden shield to deter the agitator from swaying on the road.

Employing a wooden shield to deter the agitator from swaying on the road.  Place inside a container with support from saddles and secure with reinforcing steel strips.

Place inside a container with support from saddles and secure with reinforcing steel strips. | Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

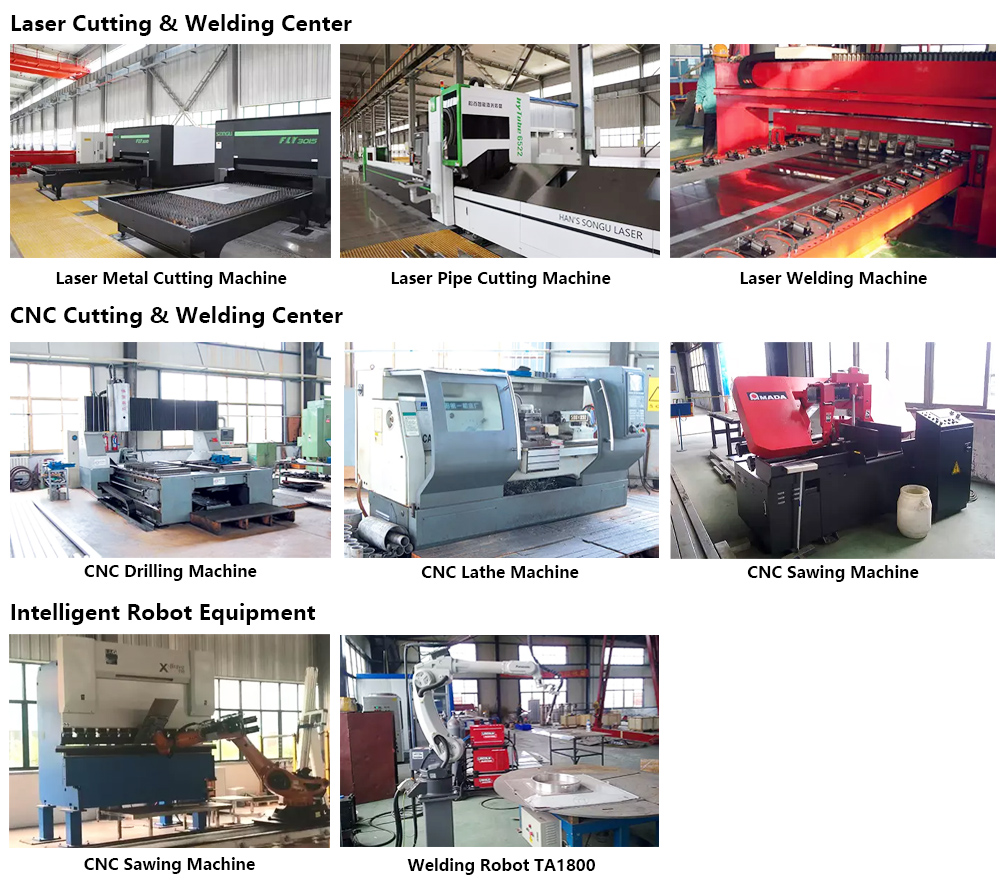

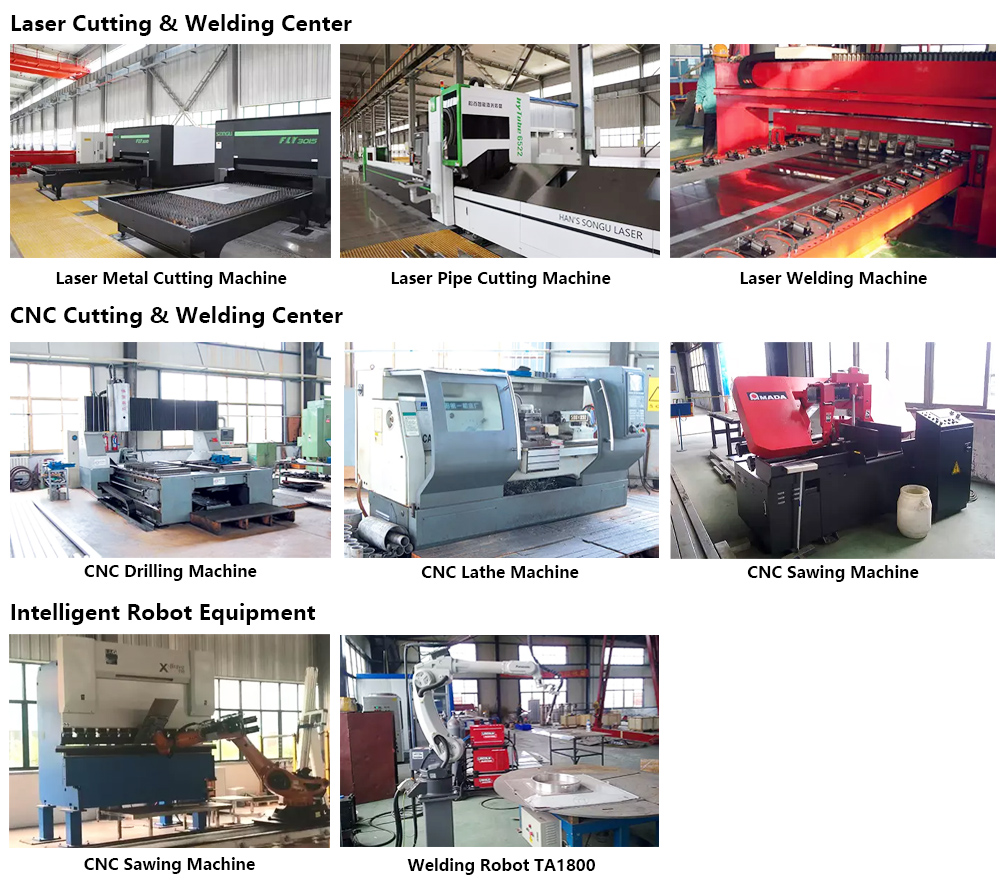

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Product description

Our SS304 Double Jacket Stainless Steel Mixer Tank is a high-performance mixing solution designed for the painting industry. Made from premium-grade SUS304 or SUS316 stainless steel,with high polishing treatment, can meet the requirements of the daily chemical industry. It offers excellent corrosion resistance and durability.

Equipped with a jacket, the jacket can be used for heating to help mix various materials evenly.

The double jacket structure provides outstanding temperature control, allowing you to heat or cool according to your process requirements.

The mixing system can be configured with various blade types to ensure uniform stirring and efficient mixing.

Normal pressure, negative pressure, and pressurized containers can be customized according to customer needs.

Additionally, optional accessories such as electric lifts, turning mechanisms, and temperature control systems can be incorporated to accommodate the specific requirements for different customers.

| Features

Corrosion resistance: Stainless steel tanks exhibit excellent corrosion resistance, ensuring the integrity of the coating materials and longevity of the equipment.

High temperature resistance: These tanks can withstand high temperatures during the mixing process, allowing for efficient and effective mixing of paint and coating materials.

Hygienic and easy to clean: Stainless steel tanks have a smooth surface that is easy to clean, promoting cleanliness and preventing contamination in the mixing process.

Optimal mixing performance: These tanks are designed with efficient mixing mechanisms, resulting in thorough and uniform blending of paint and coating materials.

Energy efficiency: Stainless steel mixing tanks are engineered to minimize energy consumption while maintaining excellent mixing performance, contributing to cost savings and environmental sustainability.

Customizable features: These tanks can be equipped with various accessories and features, such as temperature control systems, agitators, and sampling valves, allowing for tailored solutions to meet specific requirements in the paint and coating industry.The thickness of the container is customized according to customer requirements. In order to ensure safety, the thickness of the container is calculated to ensure the quality and economy of the product.

Safety guarantee: The equipment is equipped with multiple safety measures, such as overload protection and leakage protection, to ensure safety during operation.

High degree of automation: The laundry detergent mixing tank has automated functions, including automatic feeding, automatic stirring and automatic discharging, which can significantly reduce the cost of manual operations.

| Techincal parameters

| Materials | SUS304/SUS316L,Carbon Steel,Nickel Alloy,Titanium etc |

| Materials Viscosity | ≤500,000 cps,customized |

| Production Capacity | 500-3000L,customized |

| Voltage | 208/220/380/400/415/440 V, 3Phase 50/60hz |

| Certification | GMP,CE, UL,CSA,IECE,ATEX |

| Application Industry | Used for dispersing and mixing in industries such as paint, ink, adhesives, dyes, pesticides etc. |

| Temperature control | Adaptable heating/cooling methods including electric heating, steam heating or water cooling ensure customization to your requirment. |

| Drive mode | Electric drive, pneumatic drive, hydraulic drive, can be customized |

| Speed | High speed type, medium speed type, low speed type,can be customized |

| Sealed form | A variety of sealing forms are available to meet the design requirements of vacuum, normal pressure, low pressure, medium pressure and high pressure. |

| Surface treatment | PTFE coating, polyurethane coating, tungsten carbide coating, etc. |

- Stainless steel 304 construction ensures durability and corrosion resistance.

- The tank features a semi-open top with hinged lids for easy access and an oval bottom for efficient mixing.

- Both the interior and exterior of the tank are finished with a smooth 2B finish.

- Sturdy lug supports provide stability and support to the tank.

- The tank includes a half pipe heating jacket for efficient heating of the contents.

- A 1/2" sampling valve allows for easy sampling of the liquid.

- A liquid level indicator is included to monitor the level of the liquid inside the tank.

- The top agitator is equipped with a motor, gearbox, paddle agitator, rack, and mechanical seal for effective mixing.

-The tank has 2" inlet and outlet connections for convenient fluid transfer.

- A 2" drainage outlet enables easy emptying of the tank.

- A breather is installed to regulate air pressure inside the tank.

- Additional accessories, such as a control box, pump, load cell, and stainless steel pipelines, are provided for enhanced functionality.

The stainless mixer tank is offered in a versatile capacity range spanning from 500 liters to 50,000 liters, and we provide customizable options to cater to your specific needs. To obtain more detailed information, please submit an inquiry, and our team will be glad to assist you further.

| Mixer selection

| Product packing

Covered with a blanket to prevent a collision.

Covered with a blanket to prevent a collision.  Employing a wooden shield to deter the agitator from swaying on the road.

Employing a wooden shield to deter the agitator from swaying on the road.  Place inside a container with support from saddles and secure with reinforcing steel strips.

Place inside a container with support from saddles and secure with reinforcing steel strips. | Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

content is empty!