VCT-Cor

Pretank

SUS304/SUS316L

500L - 10,000L, other volume can be customized

| Availability: | |

|---|---|

Variable Capacity Tank, a must-have for artisan winemakers seeking versatile functionality. This exceptional tank is specially designed to cater to your unique winemaking requirements. With its innovative design, it can be utilized as an open-top fermentation vessel or transformed into a fully sealed storage tank when paired with a lid. Equipped with a floating lid feature, this tank allows for effortless adjustment to accommodate varying liquid levels. This ensures a consistent and controlled environment during the fermentation process, leading to exceptional results every time. For added convenience, the tank can be sealed using an air cushion gasket, providing an airtight seal that preserves the wine's integrity while preventing unwanted oxidation.

Variable Capacity Tank with Floating Lid

|

Optional Surface

2B

Oil Brushed

External Oil Brushed&Internal 2B

|

Features

Square maway & Valves

The internal weld is smooth and polished, easy to clean and without sanitary dead Angle.

Reiforced top channel and floating lid with air tube

|

Data Sheet

Structure | Variable capacity tank with floating lid and jacket |

Material | SS304 |

Jacket type | Cooling jacket |

Insulation | / |

Surface finish | 2B/oil brushed/internal welds to be grounded, picked & passivated |

Accessories | Manhole, cooling jacket, floating lid, thermometer, sampler, inlet/outlet, drainage, liquid level |

OEM/ODM | Can be customized according to customers’ requirements and productions process |

Warranty time | 2 years |

Certificate | CE/ISO |

MOQ | 1 unit |

| Model | Volume (L) | Inner dia. (mm) | Total height (mm) | Shell height H1 (mm) | Legs height H2 (mm) | Legs nos. | Cooling area (H) |

| VCT1.0 | 1000 | 1000 | 2280 | 1500 | 400 | 3 | 700 |

| VCT 1.5 | 1500 | 1200 | 2500 | 1500 | 400 | 3 | 700 |

| VCT 2.0 | 2000 | 1300 | 2600 | 1610 | 400 | 3 | 700 |

| VCT 2.5 | 2500 | 1400 | 2700 | 1720 | 400 | 4 | 700 |

| VCT 3.0 | 3000 | 1500 | 3000 | 1830 | 500 | 4 | 1000 |

| VCT 3.5 | 3500 | 1500 | 3400 | 2220 | 500 | 4 | 1000 |

| VCT 4.0 | 4000 | 1600 | 3700 | 2220 | 750 | 4 | 1000 |

| VCT4.5 | 4500 | 1700 | 3700 | 2000 | 750 | 4 | 1000 |

| VCT 5.0 | 5000 | 1800 | 3900 | 2220 | 750 | 4 | 1000 |

| VCT 6.0 | 6000 | 1800 | 4100 | 2440 | 750 | 4 | 1500 |

| VCT 7.0 | 7000 | 2100 | 3800 | 2220 | 750 | 4 | 1000 |

| VCT 8.0 | 8000 | 1800 | 4100 | 3000 | 750 | 4 | 1500 |

| VCT 9.0 | 9000 | 2100 | 4050 | 2720 | 750 | 4 | 1500 |

| VCT 10 | 10000 | 2100 | 4450 | 3000 | 750 | 4 | 1500 |

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

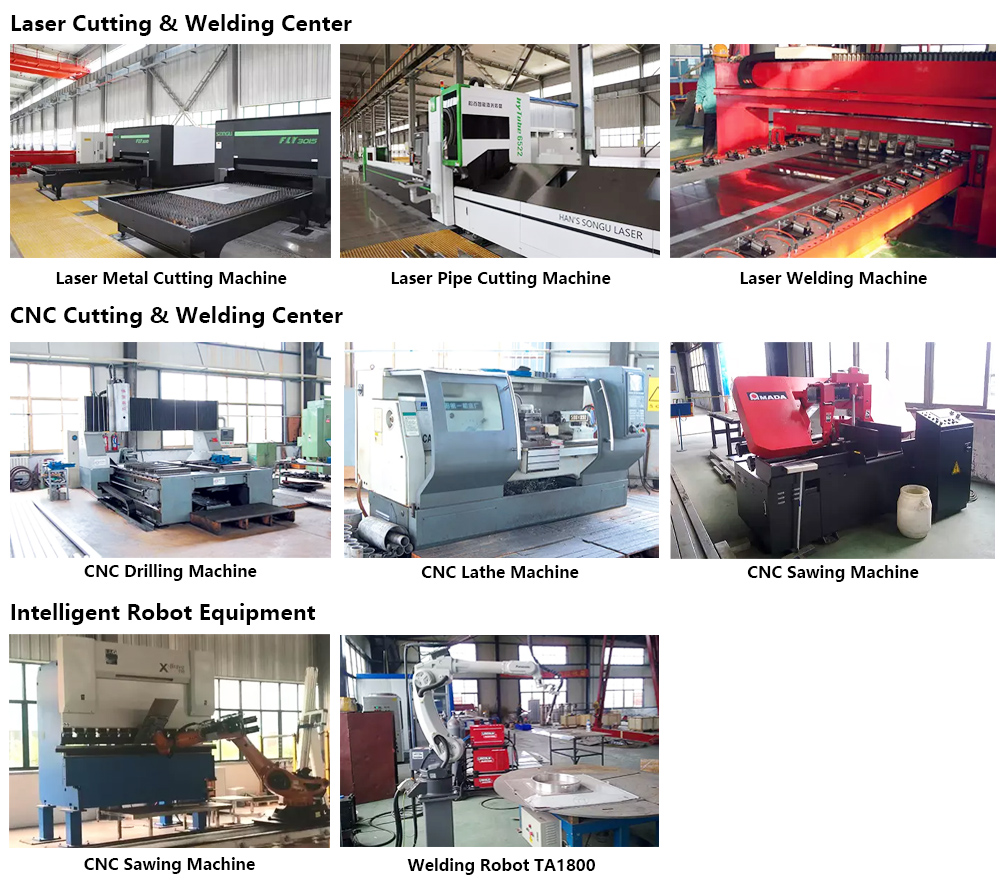

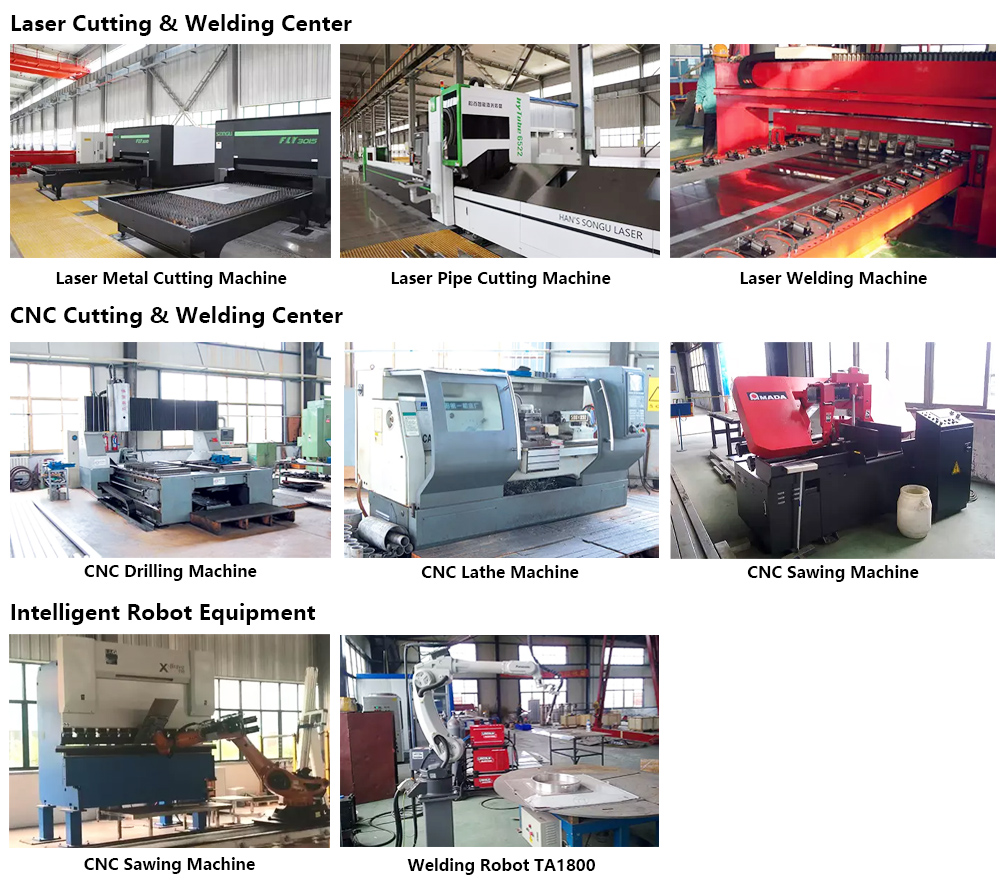

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| FAQ

1. Can you produce tanks with S.S.316L?

A: Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

2. What’s the lead time?

A: 35-50 working days depend on the order quantity.

3. How do you ship the goods?

A: We usually ship by sea in containers or flat rack.

4. Do you supply door to door shipping?

A: Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

5. What inspections will you do before delivery in your factory?

A: All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

Can't find the ideal tank with floating lid?- Lets's custom it! |

Talk to our engineers and describe your requirements. We will design a custom solution perfect for your processing needs.

Describing your needs as best, you can using the following form. Our staff will contact you with helpful suggestions and proposals. |

Variable Capacity Tank, a must-have for artisan winemakers seeking versatile functionality. This exceptional tank is specially designed to cater to your unique winemaking requirements. With its innovative design, it can be utilized as an open-top fermentation vessel or transformed into a fully sealed storage tank when paired with a lid. Equipped with a floating lid feature, this tank allows for effortless adjustment to accommodate varying liquid levels. This ensures a consistent and controlled environment during the fermentation process, leading to exceptional results every time. For added convenience, the tank can be sealed using an air cushion gasket, providing an airtight seal that preserves the wine's integrity while preventing unwanted oxidation.

Variable Capacity Tank with Floating Lid

|

Optional Surface

2B

Oil Brushed

External Oil Brushed&Internal 2B

|

Features

Square maway & Valves

The internal weld is smooth and polished, easy to clean and without sanitary dead Angle.

Reiforced top channel and floating lid with air tube

|

Data Sheet

Structure | Variable capacity tank with floating lid and jacket |

Material | SS304 |

Jacket type | Cooling jacket |

Insulation | / |

Surface finish | 2B/oil brushed/internal welds to be grounded, picked & passivated |

Accessories | Manhole, cooling jacket, floating lid, thermometer, sampler, inlet/outlet, drainage, liquid level |

OEM/ODM | Can be customized according to customers’ requirements and productions process |

Warranty time | 2 years |

Certificate | CE/ISO |

MOQ | 1 unit |

| Model | Volume (L) | Inner dia. (mm) | Total height (mm) | Shell height H1 (mm) | Legs height H2 (mm) | Legs nos. | Cooling area (H) |

| VCT1.0 | 1000 | 1000 | 2280 | 1500 | 400 | 3 | 700 |

| VCT 1.5 | 1500 | 1200 | 2500 | 1500 | 400 | 3 | 700 |

| VCT 2.0 | 2000 | 1300 | 2600 | 1610 | 400 | 3 | 700 |

| VCT 2.5 | 2500 | 1400 | 2700 | 1720 | 400 | 4 | 700 |

| VCT 3.0 | 3000 | 1500 | 3000 | 1830 | 500 | 4 | 1000 |

| VCT 3.5 | 3500 | 1500 | 3400 | 2220 | 500 | 4 | 1000 |

| VCT 4.0 | 4000 | 1600 | 3700 | 2220 | 750 | 4 | 1000 |

| VCT4.5 | 4500 | 1700 | 3700 | 2000 | 750 | 4 | 1000 |

| VCT 5.0 | 5000 | 1800 | 3900 | 2220 | 750 | 4 | 1000 |

| VCT 6.0 | 6000 | 1800 | 4100 | 2440 | 750 | 4 | 1500 |

| VCT 7.0 | 7000 | 2100 | 3800 | 2220 | 750 | 4 | 1000 |

| VCT 8.0 | 8000 | 1800 | 4100 | 3000 | 750 | 4 | 1500 |

| VCT 9.0 | 9000 | 2100 | 4050 | 2720 | 750 | 4 | 1500 |

| VCT 10 | 10000 | 2100 | 4450 | 3000 | 750 | 4 | 1500 |

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| FAQ

1. Can you produce tanks with S.S.316L?

A: Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

2. What’s the lead time?

A: 35-50 working days depend on the order quantity.

3. How do you ship the goods?

A: We usually ship by sea in containers or flat rack.

4. Do you supply door to door shipping?

A: Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

5. What inspections will you do before delivery in your factory?

A: All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

Can't find the ideal tank with floating lid?- Lets's custom it! |

Talk to our engineers and describe your requirements. We will design a custom solution perfect for your processing needs.

Describing your needs as best, you can using the following form. Our staff will contact you with helpful suggestions and proposals. |