Views: 46 Author: Site Editor Publish Time: 2024-03-05 Origin: Site

Post summary

Importance of choosing the right wine fermentation vessel

2.Six Common Wine Fermentation Vessels

2.2)Glass Carboys and Demijohns

2.4)Oak Barrels

2.5)Concrete Tanks

2.6)Clay Pots

Summary of advantages and disadvantages of each type

Considerations for choosing the right fermentation vessel based on budget and needs.

There are a few key points to consider before choosing a wine fermentation vessel.

The most important of these is the type of wine you plan to make: white or red. This decision will guide your choice of using an open fermenter for red wine or a closed fermenter for white wine.

Another key factor is how much of the grape's original character and aroma you want to retain. If you wish to retain the fruity flavors of your grapes, then a stainless steel inert fermenter may be a better choice.

Additionally, you need to consider the economics, reliability, and maintenance of your product. These factors will influence the type of wine fermentation vessel you ultimately choose.

Here are six common wine fermentation vessels

Plastic fermenters are a cheap and lightweight option. You just need to make sure it’s BPA-free, food-grade plastic.

The open top of the plastic fermenter makes it easy to reach and break the pomace cap, making the plastic fermenter ideal for red wine fermentation. Some fermentation tanks are equipped with lids and fermentation locks, and can be used for both red and white wine fermentation. But plastic scratches easily, so care must be taken when cleaning the fermenter. Another thing you should consider is bacterial spoilage. Excessive oxygen exposure may introduce spoilage microorganisms into the fermenting grape juice.

If you're looking for a versatile fermenter but can't afford a more expensive solution, consider plastic buckets and bins.

Glass Carboys: These are large cylindrical glass containers typically used for larger-scale wine production. They have a larger capacity, often holding several gallons of wine, and are relatively durable. Glass Carboys offer excellent sealing and transparency, allowing winemakers to observe the fermentation process clearly.

Glass Carboys are excellent vessels for white wine fermentation Their necks are narrow and not suitable for fermenting red wine.

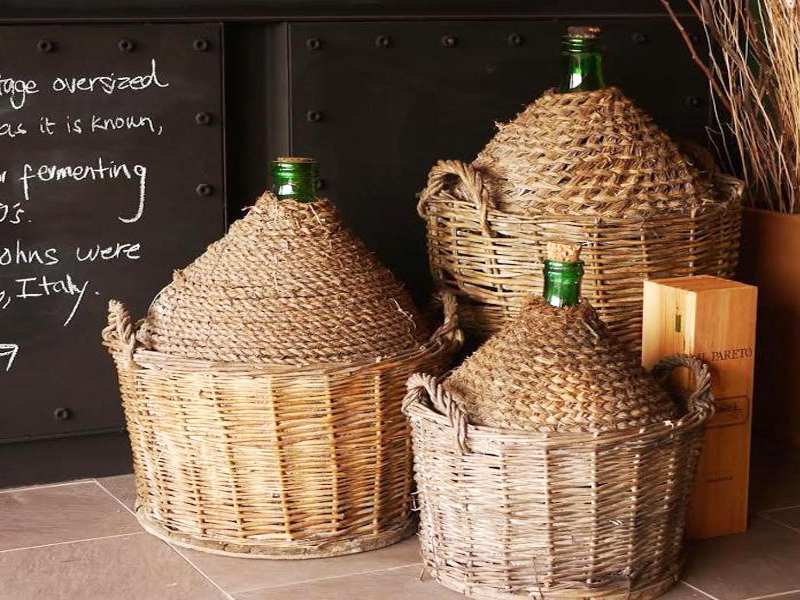

Demijohns: These are smaller glass containers, often used for small-scale or individual winemaking. Demijohns come in various shapes but typically have a rounded bottom and a narrow neck, which helps reduce oxygen exposure. They are commonly used for secondary fermentation or short- term storage of wine.

Both Glass Carboys and Demijohns have widespread applications in winemaking, with the choice depending on the scale of production and personal preferences.

Stainless Steel Tanks first appeared in the 1950s and are the most popular brewing vessels today.There are two main categories of stainless steel wine fermentation Tanks: closed top tanks and open top tanks. Closed top tanks are completely enclosed. Open-top tanks are also called variable capacity wine tanks because they have a "floating" lid. The cap is fixed to the liquid surface and moves as the liquid level changes. It can also be removed completely. This enables you to use a single tank to handle various types of wines and stages of fermentation, and even aging.

You can talk to most wine tank manufacturers and get a custom wine fermentation tank design. For example, you can adjust the size, shape, valves and fittings to your requiement. Prettech accepts fully customized designs.

Stainless steel is chemically inert and impermeable to oxygen. This means it does not impart any unwanted flavors or aromas, ensuring the quality of the wine.

If you want more control over the fermentation process, you can outfit your wine tank with a dimpled glycol cooling jacket. It will allow you to regulate the temperature inside the fermenter. Additionally, the tank can be wrapped with insulating foam to increase thermal efficiency.

Stainless steel fermenter are easy to clean and maintain, with no cracks for bacteria to hide in, polished interiors and rounded corners, and a simple hose rinse will clean them better.

Stainless steel tanks can also be equipped with wheels or forklift slots as needed for easy movement.

They are popular around the world mainly for the following reasons:

1) Durable and easy to maintain.

2) Long service life, generally well-maintained and used by customers for decades, very economical for long-term use, with high resale value.

3) Able to control the entire fermentation process very accurately

As a leading stainless steel tank manufacturer in China, prettech brings you a range of stainless steel tanks that seamlessly blend innovation and tradition.

A key advantage of choosing our products is the complete customization we offer. We understand that each winery has unique requirements, so we provide tailor-made solutions to meet individual preferences and specifications. Whether it's size, design or additional features, our team works closely with our customers to deliver custom fermenters that exceed expectations.

We have passed ISO9001/22000/45001 certificates, as well as CE, PED, API650, AS1210, AS1692, CSA and other export certificates, you can choose our products with confidence, Learn more about us!

Oak barrels have a significant impact on the flavor and texture of wine. They can give wine complex aromas, mouthfeel and structure. Generally speaking, French oak barrels usually give the wine a more delicate flavor, while American oak barrels emphasize more rich aroma and more obvious spice flavors. You can choose from different types of oak barrels depending on the style of wine you want. Also, you might consider the difference between new and old oak barrels, as new oak barrels will generally give the wine more oak flavor and aroma, while old oak barrels may be softer and more balanced.

Maintaining oak barrels is quite a hassle. The porous nature of wood gives it good aging properties but makes it difficult to clean and maintain hygiene. You will need to burn sulfur wicks regularly while the barrel is drying to reduce the ongoing danger of microbial contamination and mold growth.

In addition, wood will retain pigments, so it is best not to use a barrel to hold both red and white wines, as there may be a risk of color residue.

All things considered, oak barrels are niche wine fermenters. They are suitable for fermenting grape varieties such as Chardonnay and other white wines that can take advantage of the sensory properties of oak.

Before the era of stainless steel, concrete tanks were the most common type of fermentation tanks found in wineries.

Concrete fermenters can be customized relatively easily to suit different winemaking needs. Winemakers can choose the shape, size and finish of their tanks to have more control over the wine’s fermentation process.

In addition, because concrete has excellent thermal inertia, it can absorb and release heat stably, helping to maintain a constant temperature during the fermentation process and providing an ideal environment for yeast to ferment.

Concrete fermentation tanks have many micropores, which are perfect places for bacteria to grow, so you must disinfect your concrete tank frequently. Unlike other tanks, concrete fermentation tanks are relatively heavy, which can make them cumbersome to handle, install, and clean, especially for larger sizes.

In terms of price, concrete storage tanks are at a higher level. Combined with their low resale value, they are not the most economical option.

Clay pots are one of the oldest containers for making wine and were widely used by ancient civilizations such as Greece, Rome, Egypt, and Canaan. In recent years, in pursuit of more natural brewing, brewers around the world have once again turned their attention to this ancient pottery.

Like oak barrels, the clay of clay pots is porous, which can hold a small amount of oxygen and encourage the liquid to evaporate, creating a more concentrated wine. Unlike oak, clay is more neutral and does not impart additional flavors to the wine, allowing it to more freely express the characteristics of the terroir.

The thick clay provides natural insulation and stabilizes the temperature inside the container. This results in a lower temperature peak during primary fermentation, resulting in a brighter, fresher wine. Stable temperatures also promote malolactic fermentation, creating a more buttery flavor.

Clay fermenters are said to be naturally stable, requiring no added stabilizers or clarification chemicals. Silicon crystals in the tank walls help remove tartarates.

Although clay pots present challenges such as being labor-intensive and difficult to maintain, they remain a unique option for winemakers looking to return to their roots and focus on organic and natural production. However, production difficulty, labor input, and relative expense need to be considered before purchasing.

The above six types are currently the main wine fermentation tanks. Each of the wine fermentation tank types has its advantages and disadvantages. You need to find the right combination of versatility, durability, and fermentation control based on your budget, needs, and needs.