Views: 35 Author: Site Editor Publish Time: 2024-03-21 Origin: Site

A pump serves as a mechanical apparatus designed to convey various fluids from one location to another. Operating on hydraulic principles, it elevates fluid from lower to higher positions and shifts it from regions of low pressure to those of high pressure. By harnessing the mechanical force within the fluid, pumps convert it into pressure energy, facilitating the transfer of fluids. These devices are broadly categorized into dynamic pumps and positive displacement pumps.

Article Directory

1)Horizontal Axis Centrifugal Pump

1.1)Radial Flow Centrifugal Pump

1.2)Axial Flow Centrifugal Pump

1.3)Mixed Flow Centrifugal Pump

2.1)Line-Shaft pump

2.3)Horizontal Mounted Axial Flow Pump

1.1)Plunger Type Reciprocating Pump

1.2)Diaphgram Pump

2.1)Gear Pump

2.2)Lobe Pump

A dynamic pump refers to a type of pump that operates based on the principle of imparting kinetic energy to the fluid being pumped. This category includes Horizontal Axis Centrifugal Pumps and Vertical Turbine Pump

Working principle:

In dynamic pumps, energy is added to the fluid by mechanical means, typically through the rotation of impellers or propellers. The kinetic energy generated within the pump is then transferred to the fluid, enabling it to move from the inlet to the outlet of the pump.

Application:

Dynamic pumps are widely used in various applications where fluids need to be transported efficiently, such as water supply systems, cooling systems, industrial processes, and wastewater treatment plants.

1)Horizontal Axis Centrifugal Pump

A horizontal axis centrifugal pump is a type of dynamic pump that utilizes a horizontally oriented shaft to drive the impeller. This pump is designed with the shaft positioned horizontally, which allows for easy installation and maintenance. The impeller, mounted on the shaft, rotates rapidly within the pump casing. As the impeller rotates, it imparts kinetic energy to the fluid, causing it to move outward along the radial direction due to centrifugal force. This creates a low-pressure zone at the center of the impeller, drawing fluid from the suction inlet into the pump. The fluid is then propelled outward and discharged through the pump outlet at a higher pressure.

Application:Horizontal axis centrifugal pumps are commonly used in various applications, including water supply systems, irrigation, HVAC (heating, ventilation, and air conditioning), and industrial processes. They are favored for their efficient performance, compact design, and versatility in handling a wide range of fluids and flow rates.

Types of horizontal axis centrifugal pumps

We can classify horizontal axis centrifugal pumps into the following three types.

1.1) Radial Flow Centrifugal Pump

A radial flow centrifugal pump is a type of dynamic pump that operates by imparting kinetic energy to the fluid through a rotating impeller. In this pump design, the fluid enters the pump through the center of the impeller and is directed outward radially towards the edges of the impeller. As the fluid moves outward, it gains velocity and energy due to the centrifugal force generated by the impeller's rotation. This results in an increase in pressure, forcing the fluid to exit the pump through a discharge outlet.

Application:Radial flow centrifugal pumps are commonly used in applications where moderate to high flow rates and relatively low to moderate pressures are required, such as in water supply systems, irrigation, and chemical processing industries. They are valued for their simplicity, efficiency, and ability to handle a wide range of fluids.

1.2) Axial Flow Centrifugal Pump

An axial flow centrifugal pump is a type of dynamic pump that operates by imparting kinetic energy to the fluid through a rotating impeller. Unlike radial flow centrifugal pumps, where the fluid moves outward radially from the center of the impeller, in an axial flow pump, the fluid flows parallel to the axis of rotation of the impeller. As the impeller spins, it propels the fluid in the axial direction, thereby increasing its velocity and energy. This results in a continuous flow of fluid through the pump with minimal change in direction.

Application:Axial flow centrifugal pumps are commonly used in applications where large volumes of fluid need to be moved at relatively low pressures, such as in irrigation, drainage, flood control, and cooling systems for power plants and industrial processes. They are valued for their high efficiency, low maintenance requirements, and ability to handle large flow rates.

1.3) Mixed Flow Centrifugal Pump

A mixed flow centrifugal pump is a type of dynamic pump that combines features of both radial and axial flow pumps. In a mixed flow pump, the impeller is designed to direct fluid flow both radially outward and axially along the impeller's axis of rotation. As the impeller rotates, the fluid is drawn into the pump and flows outward radially, similar to a radial flow pump. However, at the same time, the fluid is also directed to flow in the axial direction along the impeller's axis, similar to an axial flow pump. This combination of radial and axial flow characteristics results in a pump that provides a blend of high flow rates and moderate to high pressures.

Application:Mixed flow centrifugal pumps are commonly used in applications where a balance between flow rate and pressure is required, such as in irrigation systems, drainage, flood control, and water supply for industrial processes. They offer efficient performance and versatility in handling various fluid types and flow conditions.

Advantages of Horizontal Axis Centrifugal Pumps:

Simple in Design: Horizontal axis centrifugal pumps are designed with simplicity in mind, making them easy to understand and operate.

Low Cost: These pumps are often cost-effective compared to other types of pumps, both in terms of initial purchase and long-term maintenance.

Strong and Efficient: Horizontal axis centrifugal pumps are known for their robust construction, allowing them to handle various fluids efficiently and reliably.

Low Maintenance: Due to their simple design and sturdy construction, these pumps typically require minimal maintenance over their lifespan, reducing downtime and maintenance costs.

Compact in Size: Horizontal axis centrifugal pumps are compact in size, making them suitable for installations where space is limited or where portability is required.

Low Power Consumption: These pumps are generally efficient in terms of energy consumption, helping to reduce operational costs.

Disadvantages of Horizontal Axis Centrifugal Pumps:

Poor Suction Power: Horizontal axis centrifugal pumps may have limited suction power, particularly when dealing with fluids at high elevations or long suction lines.

Cavitation and Corrosion: Cavitation, a phenomenon where vapor bubbles form in the pump due to low pressure, can cause erosion and corrosion in the impellers of horizontal axis centrifugal pumps, leading to reduced efficiency and lifespan.

Not Suitable for Viscous Fluids: Horizontal axis centrifugal pumps are not well-suited for handling highly viscous fluids, as their design relies on the fluid's ability to flow easily through the pump.

In summary, while horizontal axis centrifugal pumps offer advantages such as simplicity, cost-effectiveness, and low maintenance, they also have limitations such as poor suction power, susceptibility to cavitation, and unsuitability for viscous fluids. These factors should be considered when selecting a pump for a specific application to ensure optimal performance and longevity.

A vertical turbine pump is a type of centrifugal pump designed with a vertical shaft orientation. Unlike horizontal centrifugal pumps, which have horizontally oriented shafts, vertical turbine pumps have their shafts positioned vertically. These pumps consist of multiple stages, each containing a rotating impeller and a stationary diffuser or guide vane.

Working principle:

In operation, the vertical turbine pump draws water or other fluids from underground sources such as wells or reservoirs, through a submerged intake located at the bottom of the pump assembly. The fluid is then directed upwards through the pump stages by the rotating impellers. As the fluid passes through each stage, its pressure and velocity increase, resulting in efficient energy transfer.

Application:

Vertical turbine pumps are commonly used in applications requiring high flow rates and moderate to high discharge heads, such as water supply systems, irrigation, municipal water distribution, and industrial processes. They are particularly well-suited for deep well installations where submersible pumps may not be practical or economical. Additionally, vertical turbine pumps are known for their reliability, durability, and ease of maintenance, making them a preferred choice in various industries and water management systems.

We can classify them into the following types,Line shaft pumps,Submersible pumps and Horizontal mounted axial flow.

Line shaft pumps are a type of vertical turbine pump commonly used for extracting water from deep wells or boreholes. In this pump design, a series of impellers are mounted on a vertical shaft, which extends from the surface down to the submerged pump assembly. The impellers draw water from the well and increase its pressure as it passes through each stage. These pumps are driven by a power source located above ground, such as an electric motor or a diesel engine. Power is transmitted from the surface to the submerged pump via a long drive shaft known as a line shaft.

Application:

Line shaft pumps are preferred for applications where submersible pumps may not be suitable due to well diameter restrictions or other factors. They offer reliability, ease of maintenance, and flexibility in pump placement, making them suitable for various water supply and distribution applications, including municipal water systems, agricultural irrigation, and industrial processes.

Submersible pumps are a type of centrifugal pump designed to operate while fully submerged in the fluid being pumped. These pumps are typically installed underwater, either in a well, tank, or other fluid reservoir.

The pump's motor and pump assembly are hermetically sealed within a waterproof casing, allowing them to function safely and efficiently underwater without risk of electrical damage.

Application: Submersible pumps are commonly used for applications such as groundwater extraction, wastewater drainage, sewage pumping, and water supply systems.

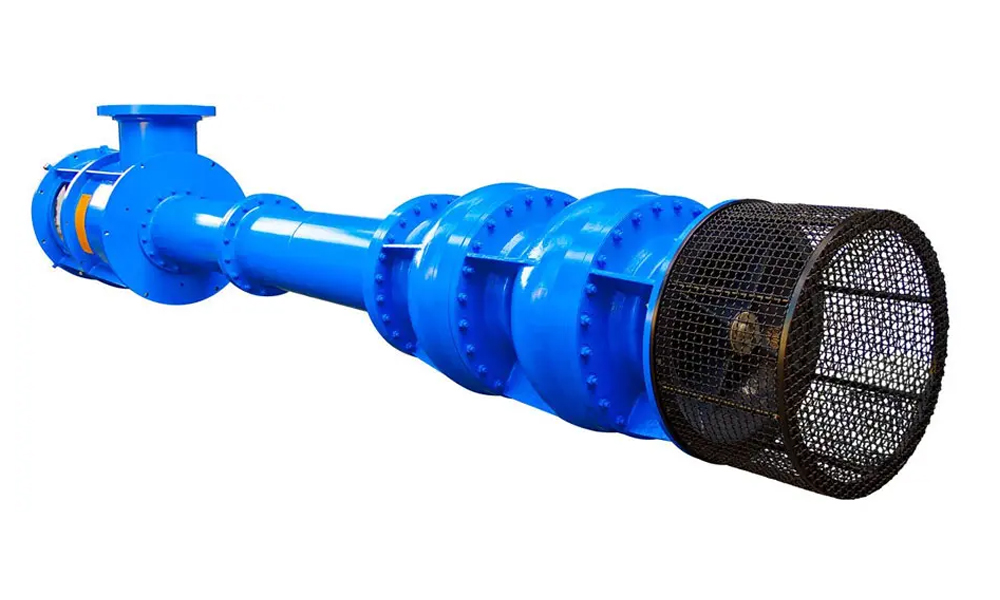

2.3)Horizontally mounted axial flow pump

A horizontally mounted axial flow pump is a type of pump where the shaft and impeller are oriented horizontally. These pumps are designed to move fluid parallel to the pump shaft, rather than radially outward like centrifugal pumps.

Application:Horizontal mounted axial flow pumps are commonly used in applications where large volumes of fluid need to be transported with minimal resistance. They are often found in industries such as agriculture for irrigation, drainage systems, flood control, and cooling water circulation in power plants and industrial processes.

Positive displacement pumps are a category of pumps that operate by repeatedly trapping a fixed volume of fluid and then displacing it into the discharge piping. Unlike dynamic pumps, which rely on kinetic energy to move fluids, positive displacement pumps use mechanical means to push the fluid forward.The key characteristic of positive displacement pumps is their ability to generate a consistent flow of fluid regardless of changes in system pressure or fluid viscosity.

Application:

They are commonly used in applications where precise flow control and the ability to handle high-viscosity fluids or solids are required, such as in chemical processing, food and beverage industries, oil and gas production, and wastewater treatment plants.

We can classify positive displacement pumps into the following types,reciprocating pump and rotary type of pump

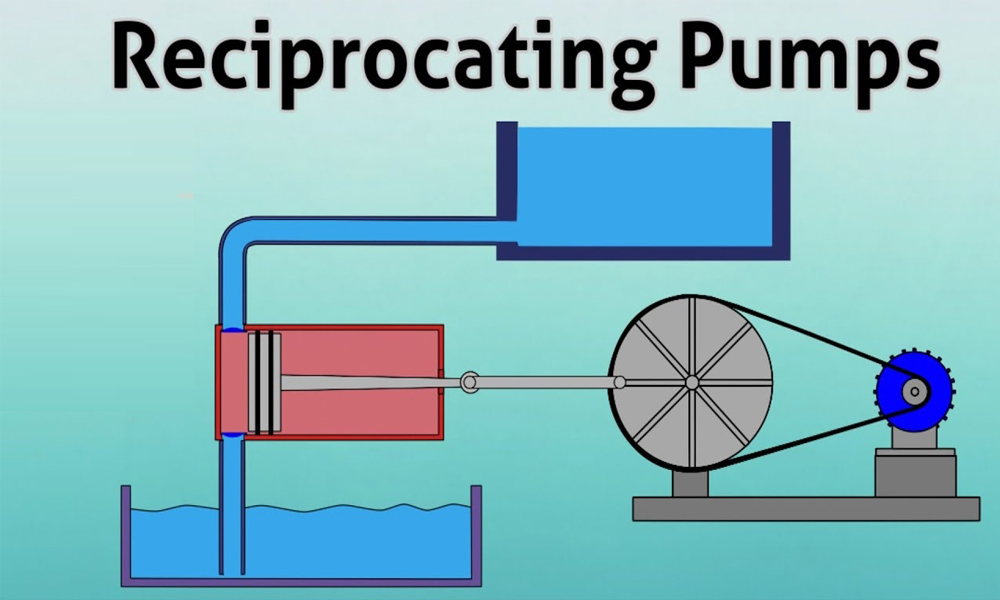

Reciprocating pumps are characterized by their use of a plunger or membrane that oscillates vertically to create pressure and propel fluid. Within this category, there are two main types of reciprocating pumps.

1.1) Plunger / Piston Type of Reciprocating Pump

The piston type of reciprocating pump operates with a piston that moves back and forth within a cylinder to generate pressure and transfer fluid.

The diaphragm pump, a type of reciprocating pump, utilizes flexible diaphragms to displace fluid through alternate compression and expansion, making it suitable for various fluid handling tasks.

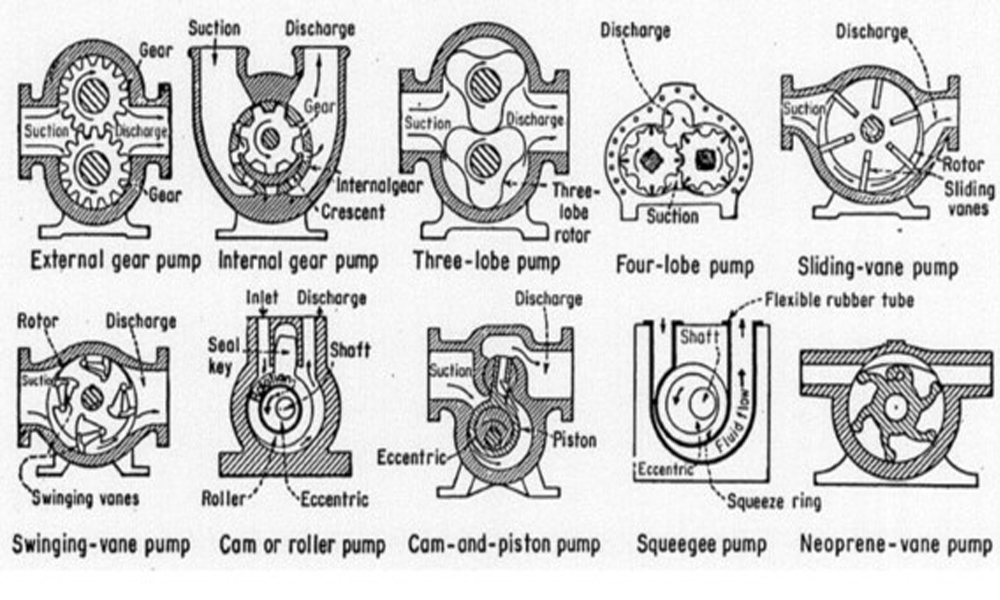

A rotary pump is a type of positive displacement pump that operates by transferring fluid through the rotation of a mechanism, such as gears or lobes, within a casing.We can classify rotary pumps into the following types.

A gear pump is a type of rotary pump that utilizes two gears to transfer fluid from the inlet to the outlet. These pumps are efficient and commonly used for pumping thick liquids like fuel and grease oil.

A rotary lobe pump is a type of positive displacement pump that uses rotating lobes to move fluid from the inlet to the outlet. This pump operates by trapping fluid between the lobes and the pump casing, allowing for the smooth and efficient transfer of various liquids, including those containing solids.

Advantages of Positive Displacement Pump:

Handling Viscous Fluids and Solids: Positive displacement pumps are capable of effectively handling high-viscosity fluids and fluids containing solids. This makes them suitable for applications where centrifugal pumps may struggle.

Constant Flow: These pumps provide a constant flow rate regardless of changes in system pressure or viscosity of the fluid being pumped. This ensures consistent performance in various operating conditions.

Pressure Increase with System Pressure: As the system pressure increases, the pressure generated by positive displacement pumps also increases proportionally. This makes them suitable for applications where varying pressure requirements are encountered.

High Efficiency Compared to Centrifugal Pumps: Positive displacement pumps are known for their high efficiency, especially when handling viscous fluids. They offer efficient energy transfer and can maintain high flow rates with relatively low power consumption.

Disadvantages of Positive Displacement Pump:

Inability to Run Dry: One of the main disadvantages of positive displacement pumps is that they cannot operate without fluid (run dry). Running a positive displacement pump without fluid can lead to overheating and damage to the pump components.

Need for Overpressure Protection: Positive displacement pumps require overpressure protection mechanisms to prevent damage in case of system blockages or pressure spikes. Without proper protection, excessive pressure buildup can lead to pump failure or damage to the system.

In summary, while positive displacement pumps offer several advantages such as handling viscous fluids, providing constant flow, and high efficiency, they also have limitations such as the inability to run dry and the need for overpressure protection. These factors should be considered when selecting a pump for a specific application to ensure optimal performance and reliability.