CHM-emf

Pretank

500L-500,000L

| Availability: | |

|---|---|

| Product Description

Emulsifying tank is ideal for emulsifying liquid mixtures. The emulsion tank efficiently carries out material processing through stirring, mixing, blending, emulsification, and homogenization.

Throughout the mixing procedure, the stirred tank allows for both manual and automatic control, enabling precise management of feeding, discharge, and stirring.Made of high-quality 304, 316L or other stainless steel, the inner surface is mirror polished and meets international sanitary standards.

Pretank adopts European high-end technology homogenizing head, high-speed tooth shearing, homogenizing and emulsifying, making the product more delicate and glossier.

| Product Parameters

-Material: SS304/SS316L

-Upper and lower heads

-Jacket

-Emulsifying mixer

-Bracket

-Manhole

-import and export

-breathing port

-Rotor pump

| Features

Efficient emulsification: Using a professionally designed and optimized emulsification structure,emulsifying tank can efficiently disperse liquid or solid ingredients into the continuous phase and achieve the formation of fine emulsified particles.

Adjustability: The emulsification tank has adjustable operating parameters, such as stirring speed, stirring time and emulsification temperature, to adapt to the emulsification requirements of different products.

Uniformity: The emulsification tank can evenly disperse solid or liquid ingredients to form a stable emulsification system.

Temperature control function: Emulsifying tank are usually equipped with a temperature control system, which can accurately control the temperature during the emulsification process and ensure product quality and stability.

Easy to operate: The emulsification tank is reasonably designed and easy to operate. It usually has an easy-to-clean structure and a convenient operating interface, allowing operators to operate, maintain and clean conveniently.

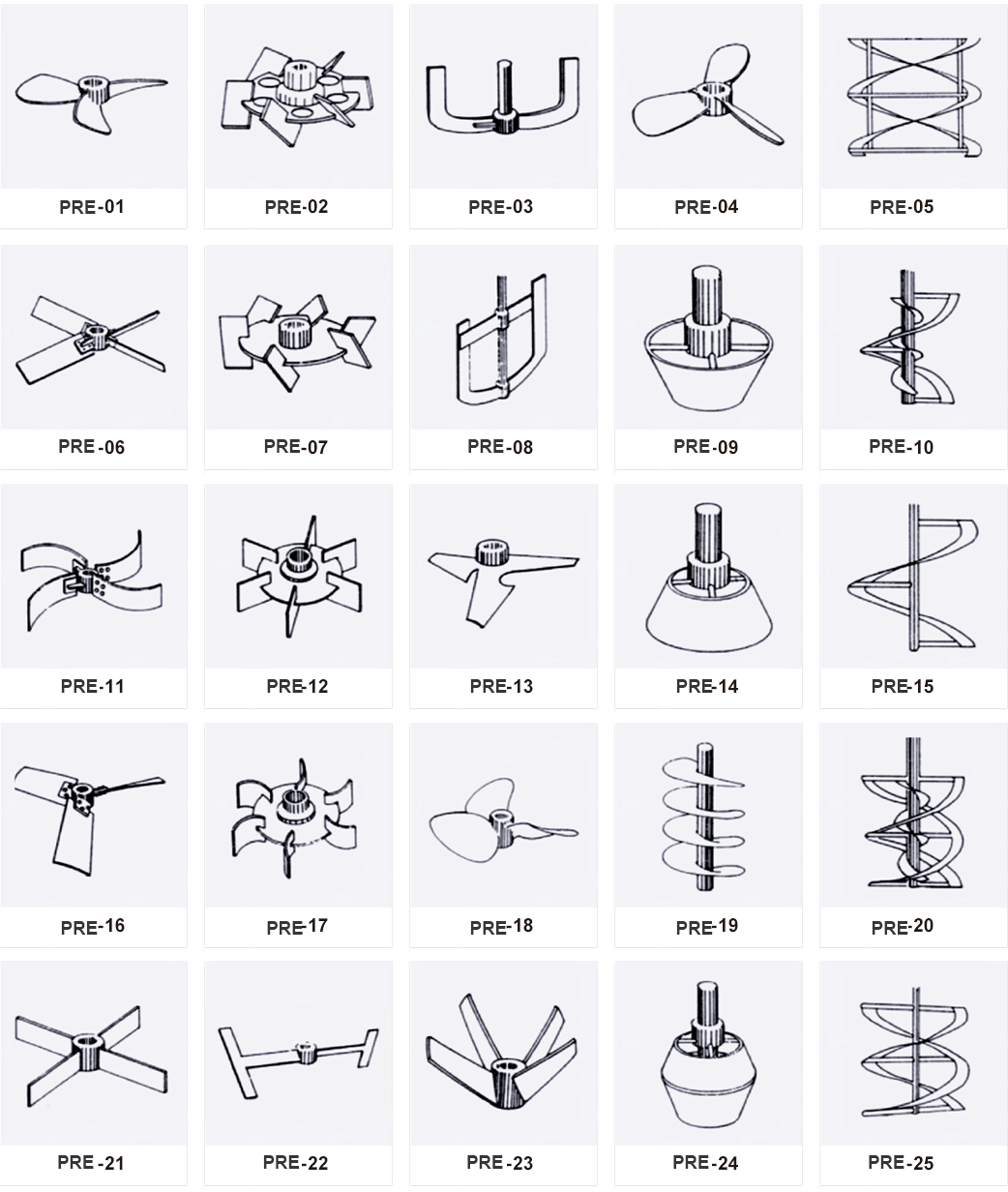

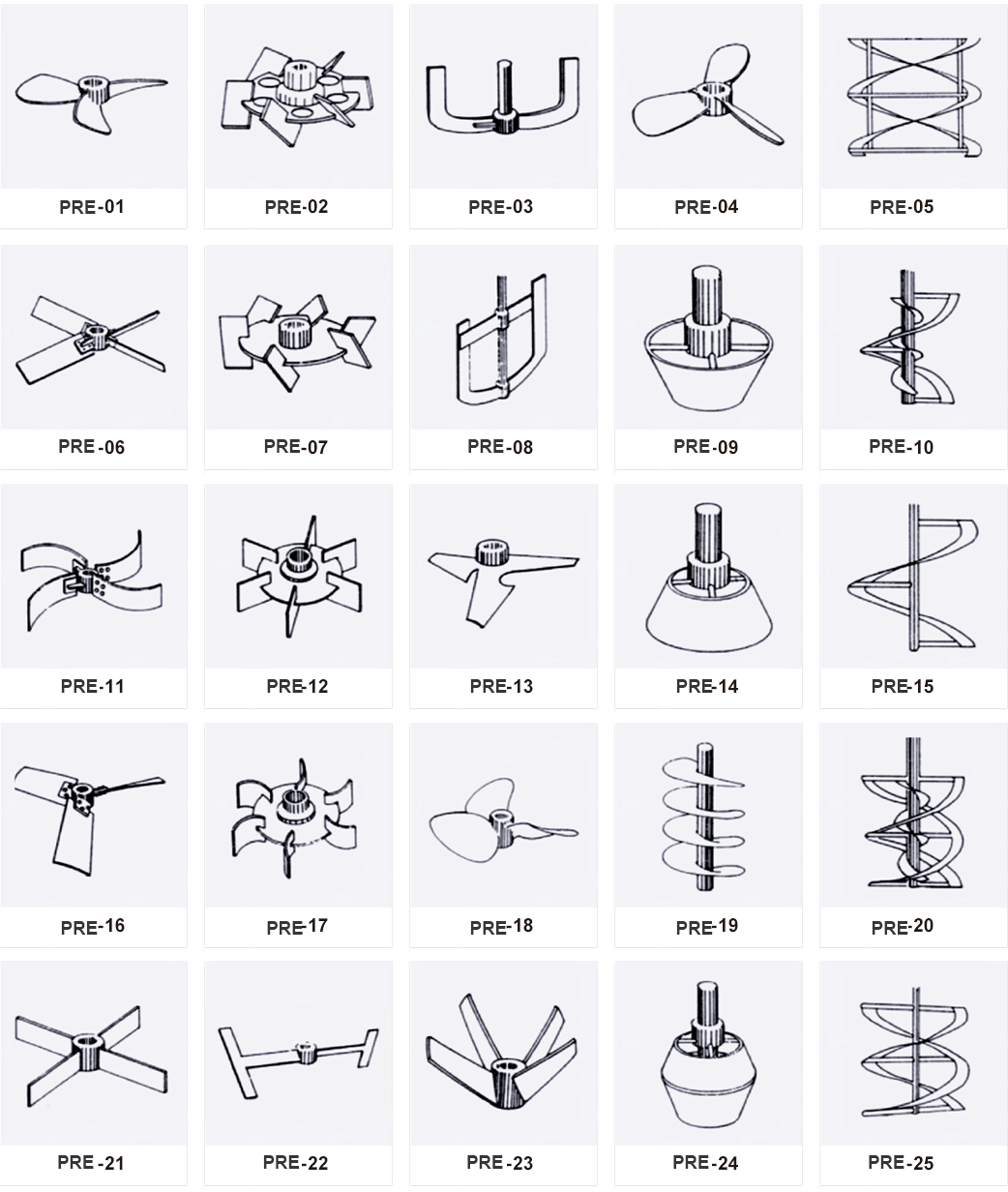

| Mixer selection

| Customer Case Picture

| FAQ

Q1. Can you produce tanks with S.S.316L?

Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

Q2. What's the lead time?

35-50 working days depend on the order quantity.

Q3. How do you ship the goods?

We usually ship by sea in containers or flat rack.

Q4. Are you factory or trading company?

We are a manufacturer and export by ourselves.

Q5. Can your factory produce according to our samples or drawing?

Yes, we can do OEM and customization.

Q6. What is your nearest port?

Qingdao port,China

Q7. Do you supply door to door shipping?

Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

Q8. How do you guarantee this machine normally operating?

Every machine is tested in our factory before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q9. Do you supply after-sale services?

Yes we do, if any defects occurred, Pretank would give instructions on how to handle, fast repair locally is available if needed.

Q10. What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

| Product Description

Emulsifying tank is ideal for emulsifying liquid mixtures. The emulsion tank efficiently carries out material processing through stirring, mixing, blending, emulsification, and homogenization.

Throughout the mixing procedure, the stirred tank allows for both manual and automatic control, enabling precise management of feeding, discharge, and stirring.Made of high-quality 304, 316L or other stainless steel, the inner surface is mirror polished and meets international sanitary standards.

Pretank adopts European high-end technology homogenizing head, high-speed tooth shearing, homogenizing and emulsifying, making the product more delicate and glossier.

| Product Parameters

-Material: SS304/SS316L

-Upper and lower heads

-Jacket

-Emulsifying mixer

-Bracket

-Manhole

-import and export

-breathing port

-Rotor pump

| Features

Efficient emulsification: Using a professionally designed and optimized emulsification structure,emulsifying tank can efficiently disperse liquid or solid ingredients into the continuous phase and achieve the formation of fine emulsified particles.

Adjustability: The emulsification tank has adjustable operating parameters, such as stirring speed, stirring time and emulsification temperature, to adapt to the emulsification requirements of different products.

Uniformity: The emulsification tank can evenly disperse solid or liquid ingredients to form a stable emulsification system.

Temperature control function: Emulsifying tank are usually equipped with a temperature control system, which can accurately control the temperature during the emulsification process and ensure product quality and stability.

Easy to operate: The emulsification tank is reasonably designed and easy to operate. It usually has an easy-to-clean structure and a convenient operating interface, allowing operators to operate, maintain and clean conveniently.

| Mixer selection

| Customer Case Picture

| FAQ

Q1. Can you produce tanks with S.S.316L?

Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

Q2. What's the lead time?

35-50 working days depend on the order quantity.

Q3. How do you ship the goods?

We usually ship by sea in containers or flat rack.

Q4. Are you factory or trading company?

We are a manufacturer and export by ourselves.

Q5. Can your factory produce according to our samples or drawing?

Yes, we can do OEM and customization.

Q6. What is your nearest port?

Qingdao port,China

Q7. Do you supply door to door shipping?

Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

Q8. How do you guarantee this machine normally operating?

Every machine is tested in our factory before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q9. Do you supply after-sale services?

Yes we do, if any defects occurred, Pretank would give instructions on how to handle, fast repair locally is available if needed.

Q10. What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

content is empty!

content is empty!