HEX-Gsk

Pretank

5㎡ to 300 ㎡

| Availability: | |

|---|---|

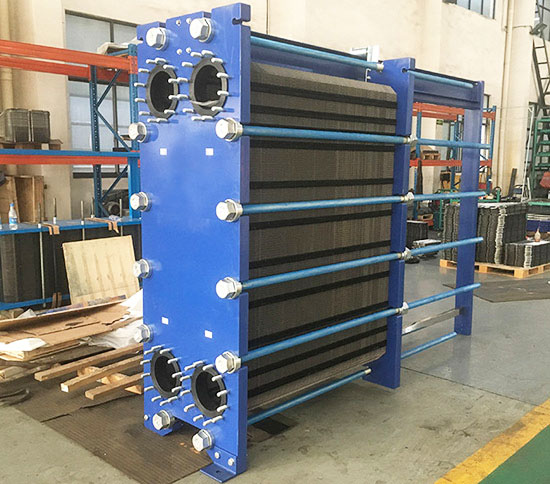

Gasket type heat exchangers can be used in the dairy industry,it can enable precise processing of food products, including heating and low-temperature pasteurization of dairy products.

The use of stainless steel ensures excellent hygiene standards and corrosion resistance, maintaining the product's quality. The compact design and efficient heat transfer capabilities of plate heat exchangers allow for precise temperature control and energy efficiency. Additionally, their easy maintenance and cleaning properties make them ideal for the dairy industry, ensuring safe and efficient heat treatment for dairy products.

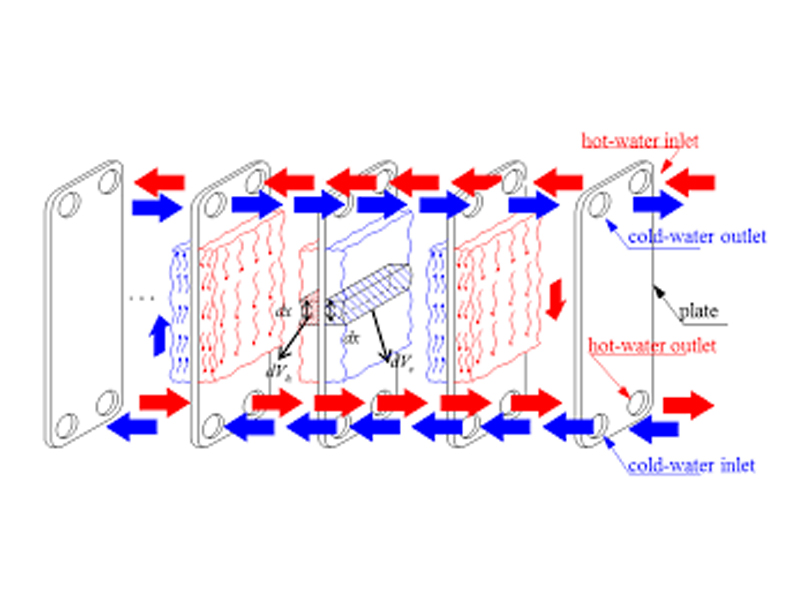

How gasket type heat exchangers work?

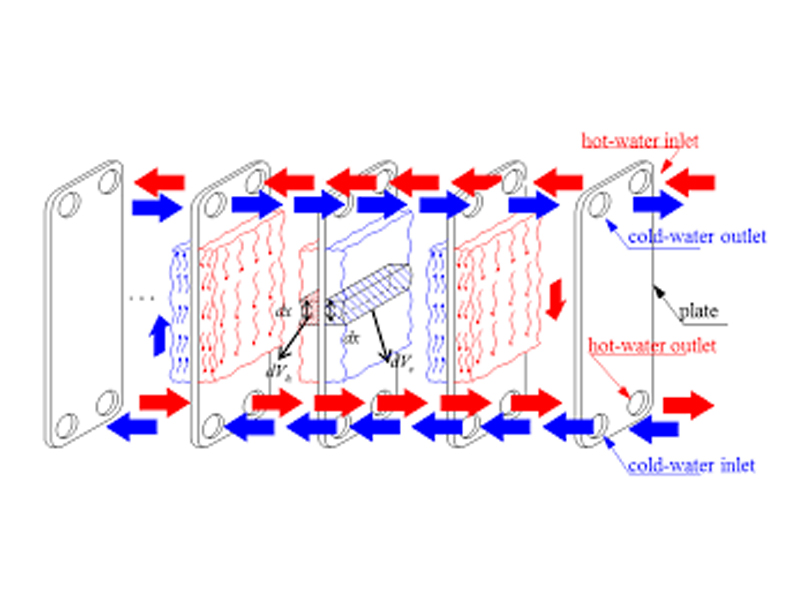

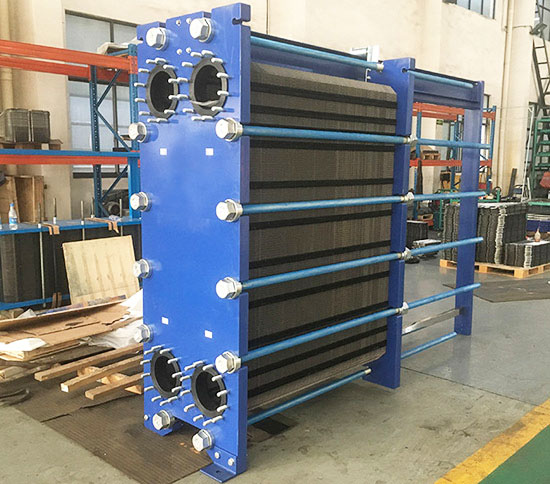

Gasketed plate heat exchangers function through a clever design utilizing elastomeric gaskets on the plates. These gaskets effectively seal the fluid channels and direct the flow into alternating channels. The plate pack, composed of the plates, is assembled between a frame plate and a pressure plate. By tightening bolts situated between these plates, the entire assembly is compressed.

For proper alignment and support, the channel plates and pressure plate are suspended from an upper carrying bar and guided by a lower guiding bar. These bars are securely fixed to the support column, ensuring stability for the heat exchanger structure.

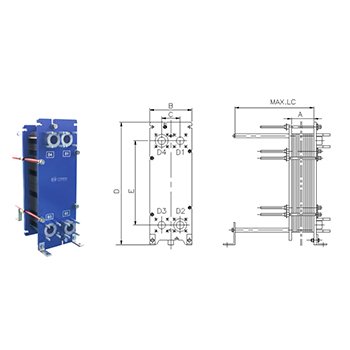

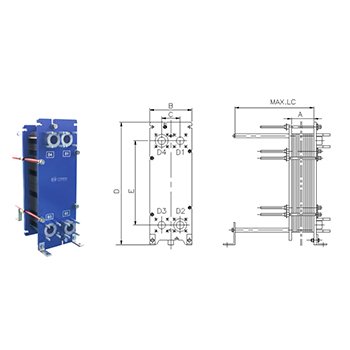

The physical design of gasketed plate heat exchangers offers numerous benefits. It facilitates easy cleaning, ensuring efficient operation and maintenance. Furthermore, the heat exchanger's capacity can be easily adjusted by adding or removing plates, providing flexibility to accommodate changing process requirements. Please refer to the accompanying diagram for a visual representation.

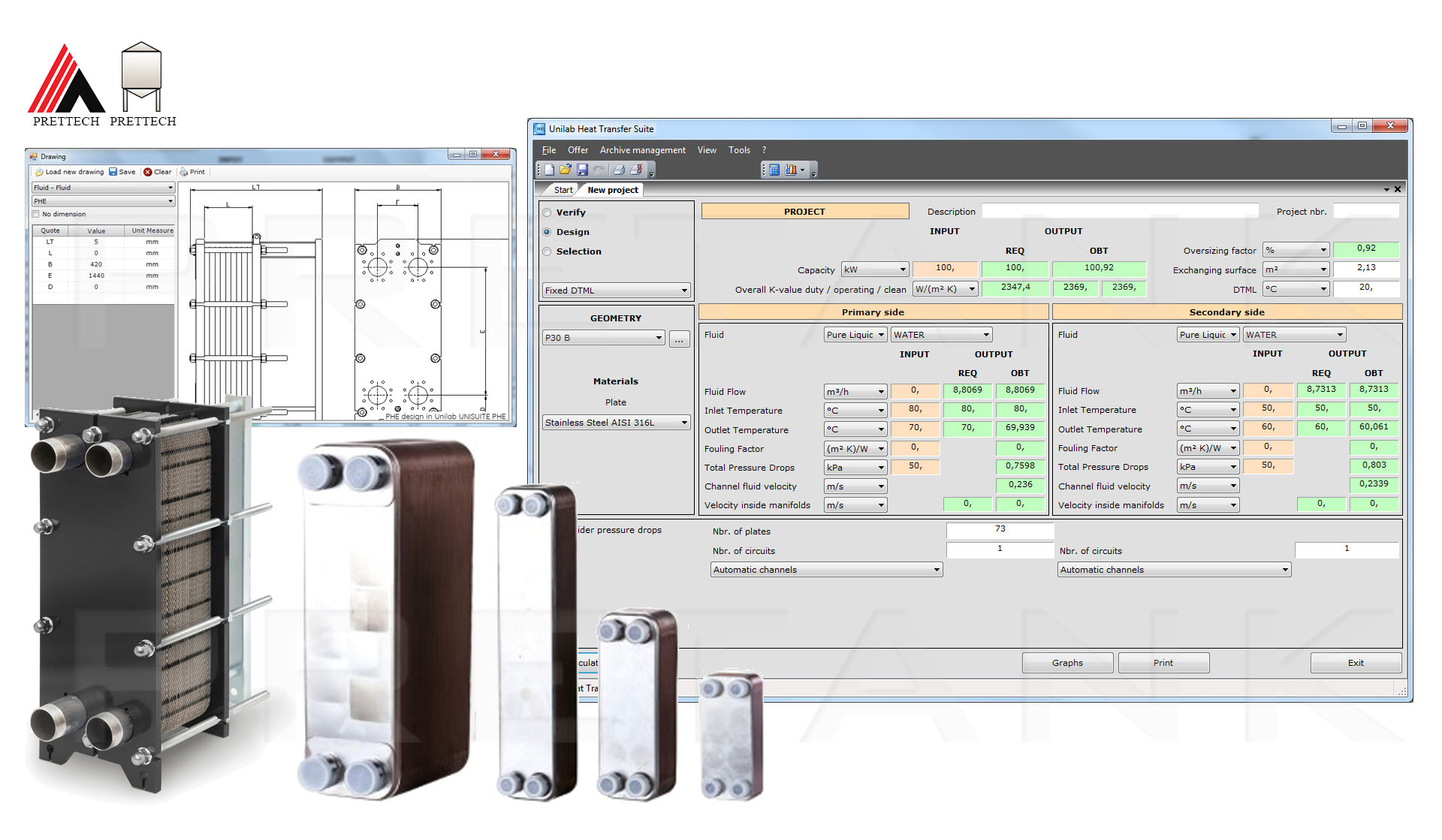

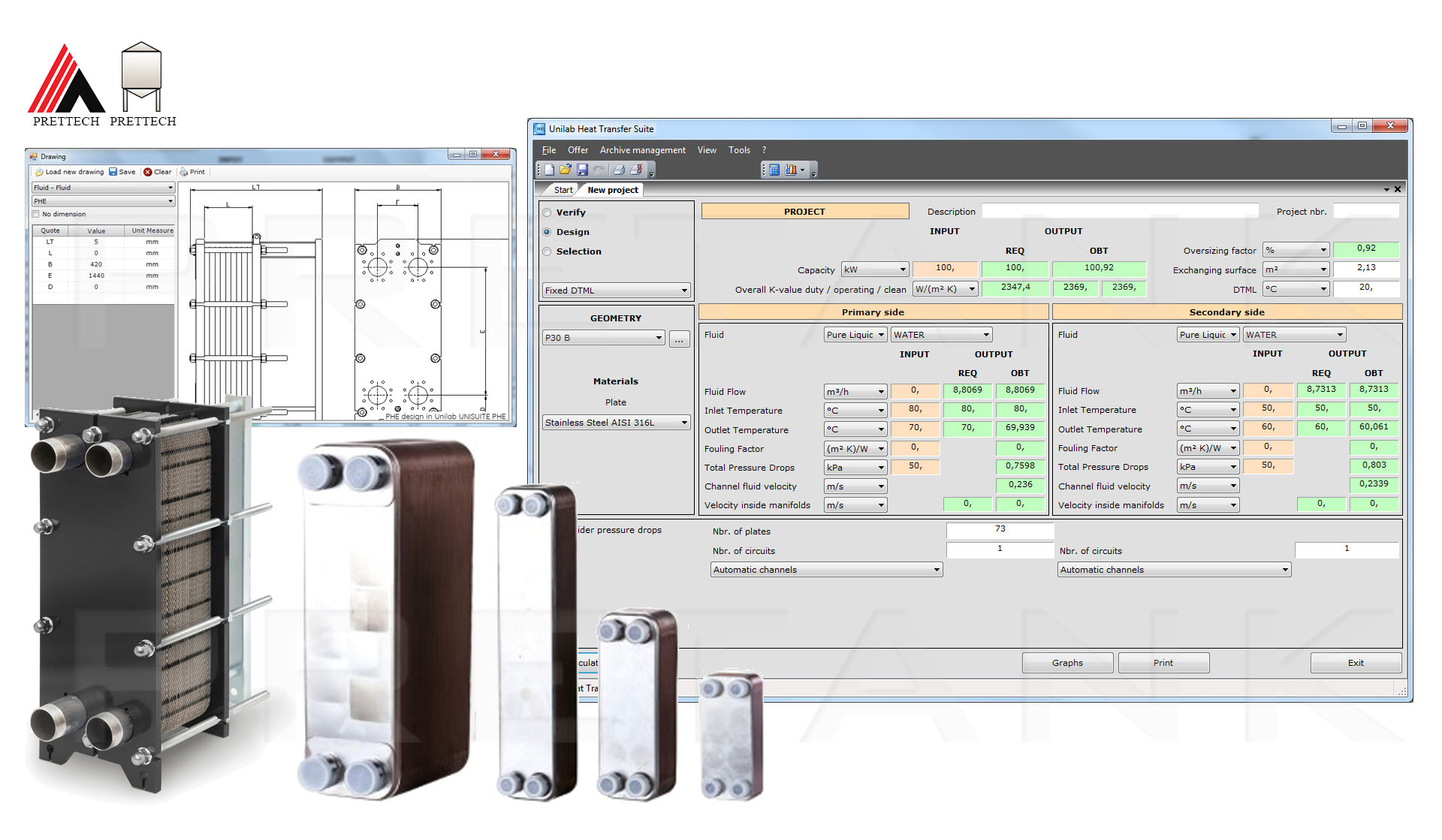

Unilab Heat Transfer Suite Design Software

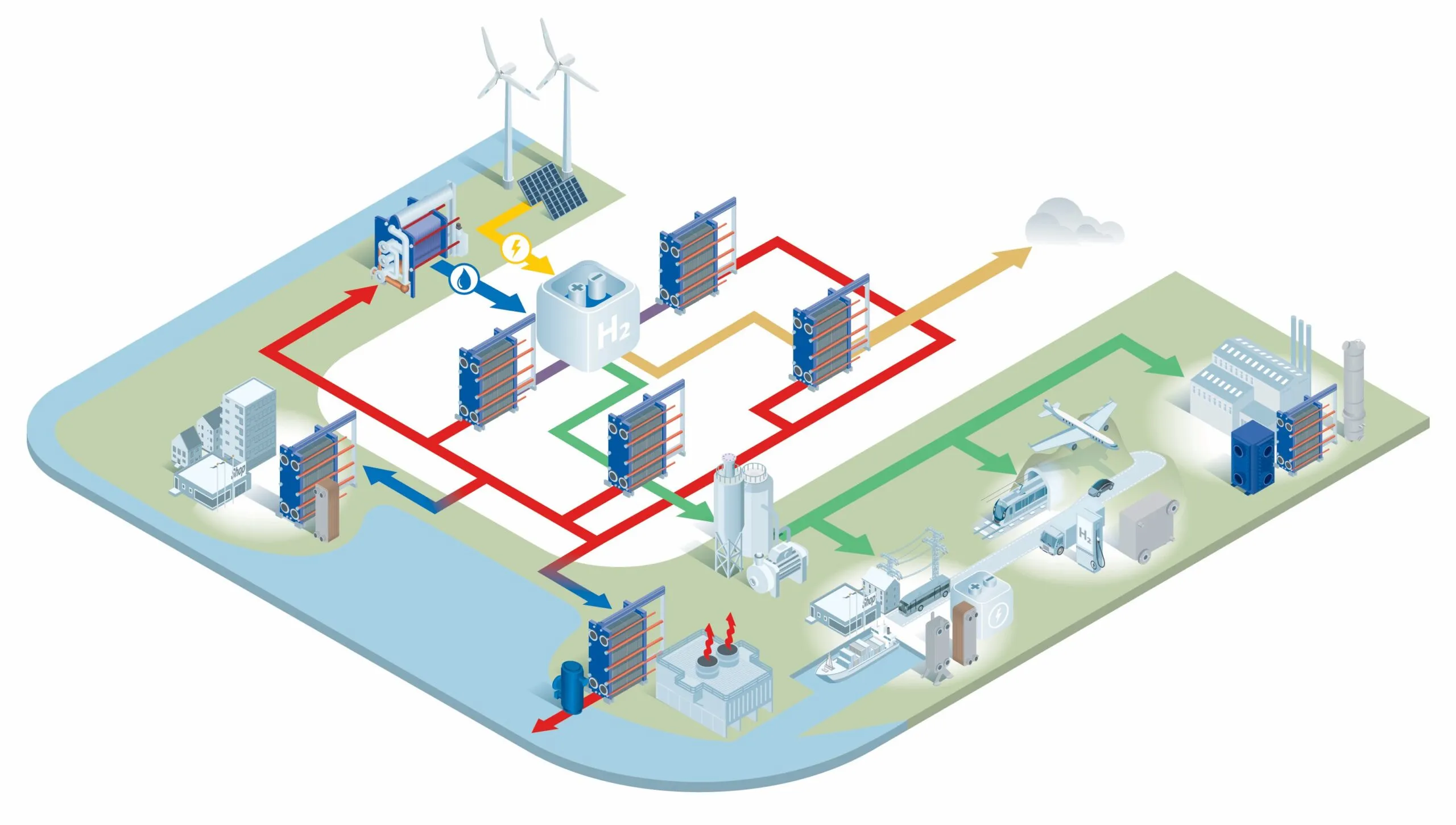

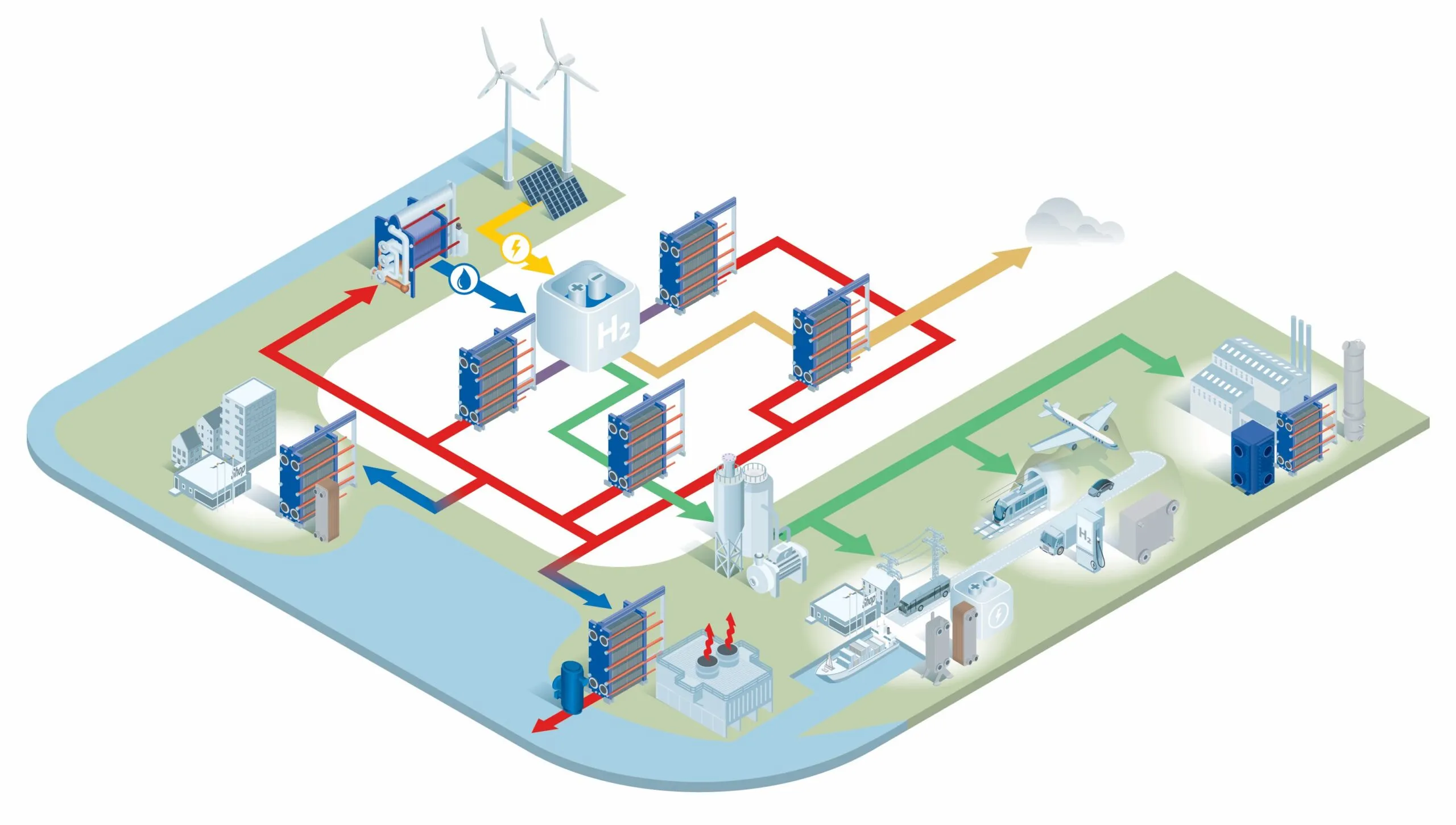

3D Image Of Working System

1.Optimal Heat Transfer: Our state-of-the-art heat exchanger technology ensures highly efficient heat transfer while maintaining complete separation between the boiler and process circuits. This critical feature eliminates any risk of product mixing, making it the perfect choice for applications where separation is of utmost importance.

2.Durable Construction: Our Gasketed Plate Heat Exchanger is carefully engineered to deliver durability and dependability. Its compact design, coupled with exceptional efficiency, is specifically tailored to meet your unique needs, providing a cost-effective solution that stands the test of time.

Our stainless steel plate heat exchangers offer a wide capacity range of 5-1200KW, with specifications tailored to your specific requirements. For more detailed information, kindly send us your Request for Quotation (RFQ). Additionally, we provide a range of other equipment including shell and tube heat exchangers, reactors, hot water tanks, dissolving tanks, alkali tanks, vacuum buffer tanks, and CIP (Clean-in-Place) systems. If you have any specific needs for these products, please feel free to inquire and we will be glad to assist you.

Project For Cooling Seawater

Project For HVAC System

| Comment & FAQ

1.What material do you do for plates?

A: We can provide a variety of materials,including Stainless Steel 304/316,titanium,graphite etc.And we give you a best solution based on the characteristics of the liquid in the shell side and tube side.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3. Is your tanks can be used locally?

A: Yes,we are 100% sure that it can be used locally. The voltage is in accordance with local regulations and the spare parts can be easily replaced locally. And our tanks can be designed according to local standards if you required.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5. Can we pay in RMB or EUR?

A: Of course.Except for payment in US dollars,we can accept payment in other currencies,such as RMB, EUR, Canadian dollar, Australian dollar, JPY which can help our customers to reduce exchange losses and simplify the payment procedures.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

7.How will you pack your goods?

A:In order to avoid the product is scratched,we will use pe film for packing or pack it according to customers special request.And we will use the wooden box has been fumigated and reinforce our goods to avoid damage during transportation.

Gasket type heat exchangers can be used in the dairy industry,it can enable precise processing of food products, including heating and low-temperature pasteurization of dairy products.

The use of stainless steel ensures excellent hygiene standards and corrosion resistance, maintaining the product's quality. The compact design and efficient heat transfer capabilities of plate heat exchangers allow for precise temperature control and energy efficiency. Additionally, their easy maintenance and cleaning properties make them ideal for the dairy industry, ensuring safe and efficient heat treatment for dairy products.

How gasket type heat exchangers work?

Gasketed plate heat exchangers function through a clever design utilizing elastomeric gaskets on the plates. These gaskets effectively seal the fluid channels and direct the flow into alternating channels. The plate pack, composed of the plates, is assembled between a frame plate and a pressure plate. By tightening bolts situated between these plates, the entire assembly is compressed.

For proper alignment and support, the channel plates and pressure plate are suspended from an upper carrying bar and guided by a lower guiding bar. These bars are securely fixed to the support column, ensuring stability for the heat exchanger structure.

The physical design of gasketed plate heat exchangers offers numerous benefits. It facilitates easy cleaning, ensuring efficient operation and maintenance. Furthermore, the heat exchanger's capacity can be easily adjusted by adding or removing plates, providing flexibility to accommodate changing process requirements. Please refer to the accompanying diagram for a visual representation.

Unilab Heat Transfer Suite Design Software

3D Image Of Working System

1.Optimal Heat Transfer: Our state-of-the-art heat exchanger technology ensures highly efficient heat transfer while maintaining complete separation between the boiler and process circuits. This critical feature eliminates any risk of product mixing, making it the perfect choice for applications where separation is of utmost importance.

2.Durable Construction: Our Gasketed Plate Heat Exchanger is carefully engineered to deliver durability and dependability. Its compact design, coupled with exceptional efficiency, is specifically tailored to meet your unique needs, providing a cost-effective solution that stands the test of time.

Our stainless steel plate heat exchangers offer a wide capacity range of 5-1200KW, with specifications tailored to your specific requirements. For more detailed information, kindly send us your Request for Quotation (RFQ). Additionally, we provide a range of other equipment including shell and tube heat exchangers, reactors, hot water tanks, dissolving tanks, alkali tanks, vacuum buffer tanks, and CIP (Clean-in-Place) systems. If you have any specific needs for these products, please feel free to inquire and we will be glad to assist you.

Project For Cooling Seawater

Project For HVAC System

| Comment & FAQ

1.What material do you do for plates?

A: We can provide a variety of materials,including Stainless Steel 304/316,titanium,graphite etc.And we give you a best solution based on the characteristics of the liquid in the shell side and tube side.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3. Is your tanks can be used locally?

A: Yes,we are 100% sure that it can be used locally. The voltage is in accordance with local regulations and the spare parts can be easily replaced locally. And our tanks can be designed according to local standards if you required.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5. Can we pay in RMB or EUR?

A: Of course.Except for payment in US dollars,we can accept payment in other currencies,such as RMB, EUR, Canadian dollar, Australian dollar, JPY which can help our customers to reduce exchange losses and simplify the payment procedures.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

7.How will you pack your goods?

A:In order to avoid the product is scratched,we will use pe film for packing or pack it according to customers special request.And we will use the wooden box has been fumigated and reinforce our goods to avoid damage during transportation.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.