Views: 19 Author: Pretank Marketing Team Publish Time: 2024-03-27 Origin: Site

Join me on a journey through time as we unravel the timeless process of crafting red wine, a tradition dating back 8,000 years. From humble grapes to the exquisite liquid in your glass, the essence of winemaking remains remarkably unchanged across the ages. Let's embark on this timeless adventure together, exploring each step from vine to wine.

While advancements in containers, presses, and cellar technologies have undoubtedly elevated the quality and efficiency of red wine production, the essence of winemaking remains beautifully simple. At its core, crafting red wine relies solely on the natural alchemy of grapes, yeast, and often sulfur dioxide as a preservative. There's no need for elaborate cooking techniques or additional ingredients. It's a harmonious dance between nature's bounty and human ingenuity, yielding a timeless elixir that captivates the senses.

The color, flavor, body and character of red wine can vary greatly depending on the grape varieties used, growing climate, winemaking techniques, aging and the overall preference of the producer. Unlike white wine, red wine also contains tannins due to prolonged contact with tannic grape skins during the winemaking process, and tannins can vary between different grapes and wine styles. Here's a detailed look at the red wine making process, giving you an insight into the fundamental techniques used in today's vineyards.

Article directory

Red wine fermentation and pressing

Waiting for the grapes to ripen, vineyard workers cut the bunches from the vines. This can be done by hand or by machine, depending on the quality requirements of the grapes.

After the harvested grapes are sent to the winery, the winemaker sorts out bad grapes and unwanted impurities. Then, use a destemmer to remove the grape stems and use a crusher to press the grapes to obtain the berries. Typically, to preserve the taste of the wine, one usually follows this stage with a dose of sulfur dioxide to kill unwanted microorganisms and minimize oxidation.

Red wine fermentation and pressing

Winemakers cool the juice, skins and seeds for a day or two, a process called cold maceration, to extract color and flavor compounds from the skins before producing alcohol.

After that, some winemakers add commercial yeast to start fermentation, while others let the natural yeasts attached to the grapes or present in the cellar air begin fermentation. Either way, the yeast cells come to life in the sweet solution and begin converting sugar into alcohol, heat, and carbon dioxide.

A skin cap forms on top of the grape juice. The caps need to be remixed into the juice at least once a day, but often more times during fermentation to keep the juice moist. Prettech's pump over fermentation tank can start cyclic spraying with one click to ensure that the solution is mixed more evenly.

This process releases carbon dioxide, absorbs oxygen, accelerates the extraction of tannins from the peel and controls heat, which can exceed 100°F if not monitored. Therefore, using our jacketed fermentation tank, you can control the temperature very conveniently.

After about five to seven days of fermentation, the grapes are ready for pressing. Extract the juice and separate the pulp and peel. The winemaker transfers the grape juice to a press, which is used to extract the juice and separate the pulp and skins.

Almost all red wine needs to be aged before it can be sold. This process can take anywhere from a few months to a few years, and the wine is aged in a variety of storage vessels, including barrels, concrete, glass, clay and stainless steel tanks. Each container affects the wine differently as it ages. Prettech offers high quality stainless steel tanks.

Oak barrels have the most obvious impact on wine. The oak itself flavors the wine with natural compounds that smell like vanilla.

Unlined concrete and clay tanks soften the wine by reducing acidity.

Stainless steel tanks are inert containers with good air tightness. They will not bring additional flavor to the wine during the fermentation process, allowing the wine to retain the aroma and flavor of the grape varieties to the maximum extent.

Of course, the biggest factor that affects the flavor of red wine is time. The longer the wine sits, the more chemical reactions occur in the liquid itself. Some people describe red wines as tasting smoother as they age.

Clarification is a key step in the wine-making process that aims to remove opaque materials from the wine and make it crystal clear. During the aging process, sediments such as dead yeast cells and tiny grape skins will settle out of the red wine, and the clarification process is usually performed after the fermentation is completed.

A common method is to transfer the wine to another large stainless steel tank and allow the floating solids in the wine to settle to the bottom of the tank, a process called racking. The "solids-free" wine can then be hosed off the top and transferred to another tank for further aging, while the solids remain at the bottom of the first tank.

Another method is to use a fining agent, a substance that attracts and binds to impurities in the wine, making them easier to remove.

The most commonly used reagents in clarification are:

1. Bentonite: A type of clay used to remove proteins from wine and increase its clarity.

2. Gelatin: A protein-based clarifying agent derived from animal collagen, usually from pork or beef.

3. Casein: Another protein clarifier derived from milk.

4. Activated Charcoal: A highly porous material that helps remove unwanted color, flavor and odor compounds from wine.

5. Isinglass: A fining agent made from the swim bladder of a fish, usually a sturgeon, used to remove sediment from wine.

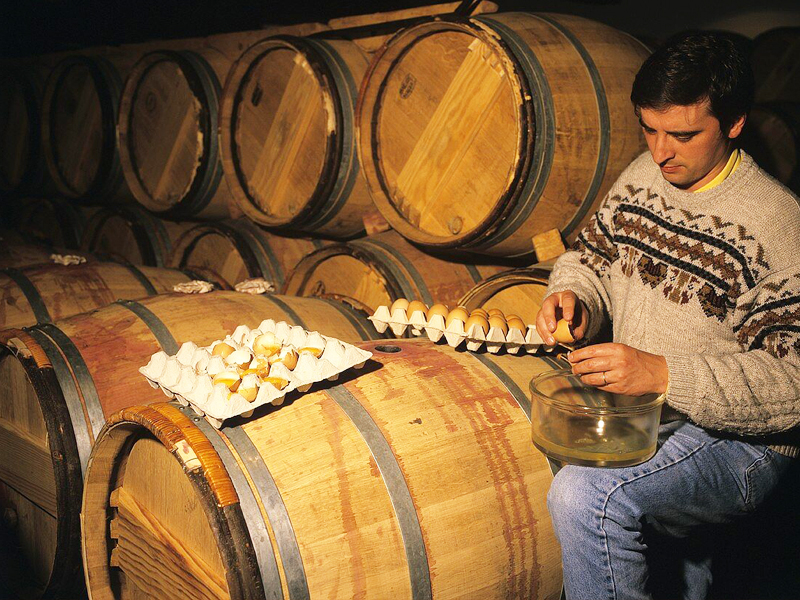

6. Egg white: A natural protein clarifying agent that helps improve the clarity and texture of wine.

Regardless of the method used, clarification is an important step in ensuring that the wine is clear and smooth on the palate.

When the wine is mature enough to be bottled, it needs to be sterile-filtered to remove any remaining yeast and subsequent microorganisms that may spoil the wine.

A modest amount of sulfur dioxide is often added to wine before bottling. This can be done by adding a sulfur dioxide solution to the entire batch of wine, or by using solid sulfur dioxide powder, which is usually added at the last minute before bottling. The addition of sulfur dioxide helps protect the wine from the effects of bacteria and oxidation, while also maintaining its freshness and fruity flavor. However, some people may be allergic to sulfur dioxide, so wine bottles often have a "contains sulfur dioxide" label to warn sensitive people.

Today's winemakers have more options, techniques, and techniques than their ancient predecessors. But the goal remains the same: take sweet grapes and let the yeast transform them into a delightful red wine.

Now, let's start enjoying the gifts of nature.