Views: 20 Author: Pretank Marketing Team Publish Time: 2024-03-20 Origin: Site

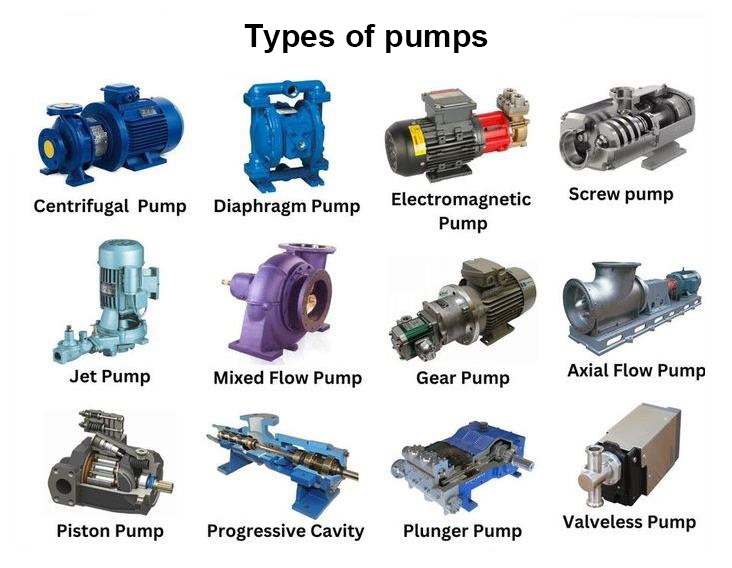

A pump is a mechanical device designed to move fluids (liquids or gases) from one place to another. It operates by creating a pressure difference to push the fluid through a system. Pumps are used in various applications across industries such as water supply, irrigation, wastewater treatment, oil and gas extraction, chemical processing, HVAC systems, and many others. They come in different types, including centrifugal pumps, positive displacement pumps, diaphragm pumps, and others, each suited to particular applications and fluid properties.

Selecting the right pump for a specific application involves considering several factors to ensure optimal performance and efficiency. Here's a step-by-step guide on how to select a pump, We recommend that you also read about the different types of pumps and their applications.

1.Define Application Requirements:

Determine the type of fluid to be pumped (water, chemicals, oil, etc.).

Specify the flow rate (volume per unit time) required for the application.

Determine the total dynamic head (TDH), which includes the vertical lift and friction losses in the piping system.

Identify any special requirements such as temperature, viscosity, solids content, and chemical compatibility.

2.Understand Pump Types:

Research different types of pumps available and their respective advantages and limitations.

Consider factors such as efficiency, reliability, maintenance requirements, and initial cost.

Following types of pumps are available according to pump mechanical configuration and their working principle.

2.1Dynamic Pump

2.1.1Horizontal Axis Centrifugal Pump

2.1.1.1Radial Flow Centrifugal Pump

2.1.1.2Axial Flow Centrifugal Pump

2.1.1.3Mixed Flow Centrifugal Pump

2.1.2Vertical Turbine Pump

2.1.2.1Line-Shaft

2.1.2.2Submersible Pump

2.1.2.3Horizontal Mounted Axial Flow Pump

2.2 Positive Displacement Pump

2.2.1Reciprocating Pump

2.2.1.1Plunger Type Reciprocating Pump

2.2.1.2Diaphgram Pump

2.2.2Rotary Pump

2.2.2.1Gear Pump

2.2.2.2Lobe Pump

Learn more about Different Types of Pumps And Their Applications.

3.Evaluate Pump Characteristics:

Compare pump performance curves provided by manufacturers to ensure they meet the required flow rate and head conditions.

Assess pump efficiency, NPSH (Net Positive Suction Head) requirements, and operating speed compatibility with the application.

4.Consider System Compatibility:

Ensure the pump is compatible with the existing piping system, including pipe size, fittings, and connections.

Consider factors such as inlet and outlet conditions, pipe material, and layout restrictions.

5.Assess Operating Conditions:

Evaluate the operating environment, including temperature, pressure, altitude, and potential hazards (e.g., corrosive or abrasive materials).

Determine if the pump will operate continuously or intermittently and assess duty cycle requirements.

6.Account for Maintenance and Lifecycle Costs:

Consider the maintenance requirements, including spare parts availability, accessibility for servicing, and estimated maintenance costs.

Evaluate the lifecycle cost, including initial purchase price, energy consumption, and expected lifespan of the pump.

7.Seek Expert Advice:

Consult with pump manufacturers, distributors, or experienced engineers to discuss specific application requirements and receive recommendations.

Utilize online resources, pump selection software, and industry guidelines to assist in the selection process.

8.Review and Finalize Selection:

Compare the options based on all the factors considered, weighing the advantages and disadvantages of each pump.

Select the pump that best meets the application requirements while considering factors such as reliability, efficiency, compatibility, and lifecycle cost.

By following these steps and carefully evaluating the application requirements and pump characteristics, you can ensure the selection of a pump that will deliver reliable and efficient performance for your specific needs.