FLT-bg

Pretank

| Availability: | |

|---|---|

| Product description

Stainless steel bag filters represent a versatile filtration solution characterized by a modern design, compact size, straightforward and adaptable operation, energy efficiency, high effectiveness, enclosed operation, and robust versatility.

Comprising essential components such as the filter cylinder, filter cylinder head with a quick-opening mechanism, and a reinforced stainless steel bag support mesh, this filter series operates under pressure. The raw liquid enters the reinforced mesh through the inlet, undergoes pressurization, and the filtered product exits through the discharge port for further processing. Impurities are efficiently captured by the filter bag, ensuring a streamlined process with the added convenience of easily replacing filter bags and minimal material consumption.

| Technical paramenters

Model | Bag qty (pcs) | Filtering area (㎡) | Flow(water) M3 | Inlet dia. (mm) | Dimension(dia.*H) (mm) |

Filter-B-1P3S | 1 | 0.1 | 8 | DN25 | 114x360 |

Filter-B-1P4S | 1 | 0.20 | 15 | DN25 | 114x520 |

Filter-B-1P1S | 1 | 0.25 | 20 | DN50 | 200*600 |

Filter-B-1P2S | 1 | 0.5 | 40 | DN50 | 200*995 |

Filter-B-2P2S | 2 | 1 | 80 | DN80 | 400x1130 |

Filter-B-3P2S | 3 | 1.5 | 120 | DN100 | 450x1150 |

Filter-B-4P2S | 4 | 2 | 160 | DN100 | 500x1315 |

Filter-B5P2S | 5 | 2.5 | 200 | DN125 | 550x1355 |

Filter-B6P2S | 6 | 3 | 240 | DN125 | 600x1390 |

Filter-B-7P2S | 7 | 3.5 | 280 | DN150 | 650x1410 |

Filter-B-8P2S | 8 | 4 | 320 | DN150 | 700x1460 |

Filter-B-10P2S | 10 | 5 | 400 | DN150 | 800x1510 |

Filter-B-12P2S | 12 | 6 | 480 | DN150 | 850x1555 |

Filter-B-14P2S | 14 | 8 | 560 | DN150 | 950x1580 |

Filter-B-16P2S | 16 | 8 | 640 | DN150 | 1000x1580 |

Filter-B-18P2S | 18 | 8 | 720 | DN150 | 1100x1580 |

Filter-B-20P2S | 20 | 8 | 800 | DN150 | 1150x1580 |

Filter-B-24P2S | 24 | 8 | 960 | DN150 | 1250x1580 |

Filter-B-28P2S | 28 | 8 | 1120 | DN150 | 1300x1580 |

| Features

1)Bag filters boast a substantial capacity, compact size, and high pollution-holding capability.

2)Leveraging the operational principles and design of the bag filter system, changing the filter bag is a swift and convenient process, eliminating the need for cleaning and saving both time and labor.

3) The filter bags exhibit a minimal rate of leakage, ensuring effective and reliable filtration.

4) Bag filters can withstand significant working pressures, offering low pressure loss and operating costs, thereby delivering noticeable energy-saving benefits.

5) The filtration precision of the filter bags has continuously advanced, achieving a remarkable 0.5um.

6) With a versatile range of applications, the bag filter accommodates various solid and liquid filtration needs, providing flexibility through diverse installation methods.

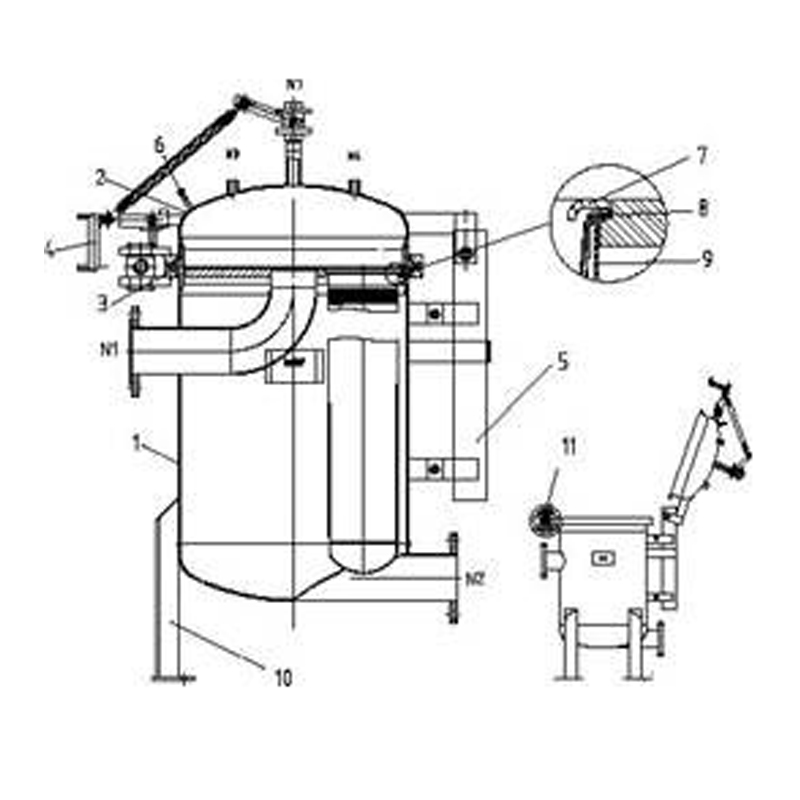

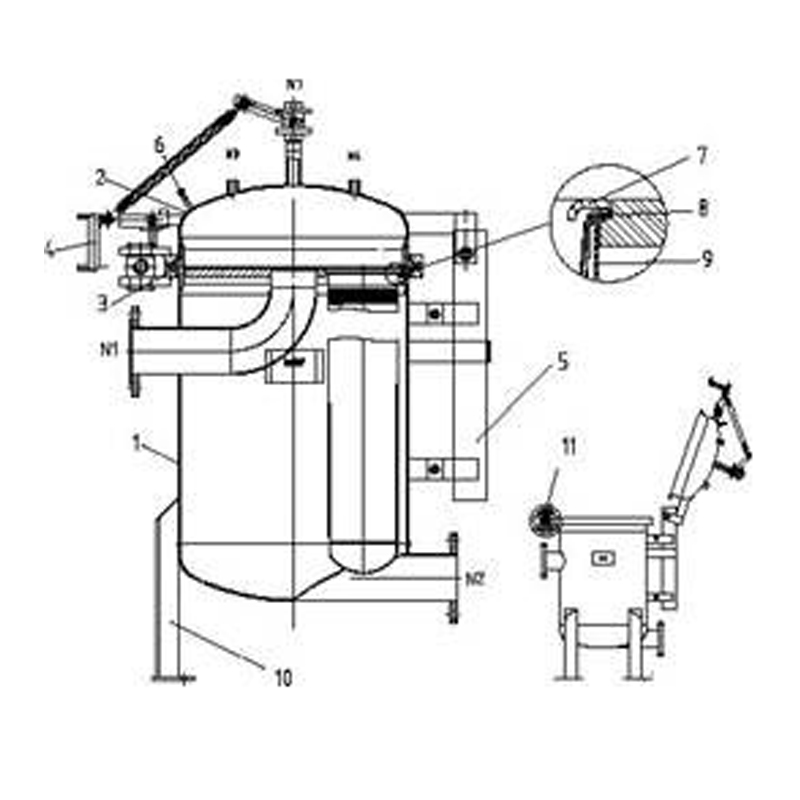

| Structure diagram

| Application

● Paintings

● Printing oils

● Beverages

● Chemicals

● Cosmetics

| Accessories and details displayed

| Product description

Stainless steel bag filters represent a versatile filtration solution characterized by a modern design, compact size, straightforward and adaptable operation, energy efficiency, high effectiveness, enclosed operation, and robust versatility.

Comprising essential components such as the filter cylinder, filter cylinder head with a quick-opening mechanism, and a reinforced stainless steel bag support mesh, this filter series operates under pressure. The raw liquid enters the reinforced mesh through the inlet, undergoes pressurization, and the filtered product exits through the discharge port for further processing. Impurities are efficiently captured by the filter bag, ensuring a streamlined process with the added convenience of easily replacing filter bags and minimal material consumption.

| Technical paramenters

Model | Bag qty (pcs) | Filtering area (㎡) | Flow(water) M3 | Inlet dia. (mm) | Dimension(dia.*H) (mm) |

Filter-B-1P3S | 1 | 0.1 | 8 | DN25 | 114x360 |

Filter-B-1P4S | 1 | 0.20 | 15 | DN25 | 114x520 |

Filter-B-1P1S | 1 | 0.25 | 20 | DN50 | 200*600 |

Filter-B-1P2S | 1 | 0.5 | 40 | DN50 | 200*995 |

Filter-B-2P2S | 2 | 1 | 80 | DN80 | 400x1130 |

Filter-B-3P2S | 3 | 1.5 | 120 | DN100 | 450x1150 |

Filter-B-4P2S | 4 | 2 | 160 | DN100 | 500x1315 |

Filter-B5P2S | 5 | 2.5 | 200 | DN125 | 550x1355 |

Filter-B6P2S | 6 | 3 | 240 | DN125 | 600x1390 |

Filter-B-7P2S | 7 | 3.5 | 280 | DN150 | 650x1410 |

Filter-B-8P2S | 8 | 4 | 320 | DN150 | 700x1460 |

Filter-B-10P2S | 10 | 5 | 400 | DN150 | 800x1510 |

Filter-B-12P2S | 12 | 6 | 480 | DN150 | 850x1555 |

Filter-B-14P2S | 14 | 8 | 560 | DN150 | 950x1580 |

Filter-B-16P2S | 16 | 8 | 640 | DN150 | 1000x1580 |

Filter-B-18P2S | 18 | 8 | 720 | DN150 | 1100x1580 |

Filter-B-20P2S | 20 | 8 | 800 | DN150 | 1150x1580 |

Filter-B-24P2S | 24 | 8 | 960 | DN150 | 1250x1580 |

Filter-B-28P2S | 28 | 8 | 1120 | DN150 | 1300x1580 |

| Features

1)Bag filters boast a substantial capacity, compact size, and high pollution-holding capability.

2)Leveraging the operational principles and design of the bag filter system, changing the filter bag is a swift and convenient process, eliminating the need for cleaning and saving both time and labor.

3) The filter bags exhibit a minimal rate of leakage, ensuring effective and reliable filtration.

4) Bag filters can withstand significant working pressures, offering low pressure loss and operating costs, thereby delivering noticeable energy-saving benefits.

5) The filtration precision of the filter bags has continuously advanced, achieving a remarkable 0.5um.

6) With a versatile range of applications, the bag filter accommodates various solid and liquid filtration needs, providing flexibility through diverse installation methods.

| Structure diagram

| Application

● Paintings

● Printing oils

● Beverages

● Chemicals

● Cosmetics

| Accessories and details displayed

About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

content is empty!