FV

Pretank

50L - 5000L

| Availability: | |

|---|---|

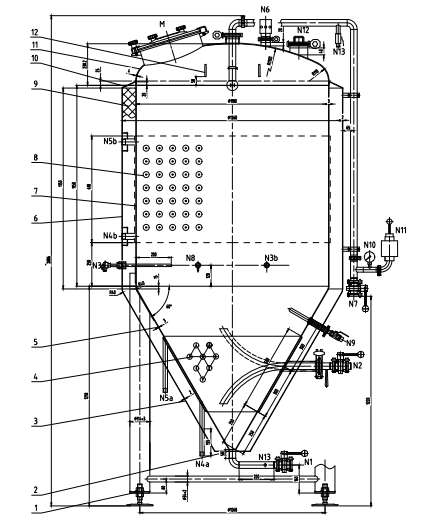

| Product Description

Wort is pumped into Beer fermentation tank for fermenting with the support of yeast and oxygen for 7-21 days at temperature between7℃~22℃,coolant would be used for cooling down the temperature,and pressure controlling devices are used for operating the beer fermenting tanks,sugar is converted to alcohol in Prettech beer fermenting tank(CCS).

Prettech construct the brewing fermenting tanks with high quality stainless steel 304 material, the shell is cylindrical, it has big conical angle on the bottom for easy exhaust and recycle yeast,dished top for better pressure bearing.

| Product Configuration

Material:SS304

Finish: Exterior brushed, interior polished<0.4um,welds grounded sanitary.

Head space: 25%.

Designing/working pressure: 0.2MPa, --0.1MPa.

Dished top, conical bottom 60 degree.

Dimple jacket on shell and bottom.

Glycol water inlet/outlet .

Insulation PU foam material 80mm thick and 2mm S/S cladding

4 legs with adjustable feet.

Elliptical manhole 450*350mm.

Outlet&drain port with tri clamp and butterfly valve.

Temperature probe PT100 and thermometer.

Solenoid valve.

Safety valve.

CIP ball and tubes with tri clamp and valve.

Pressure vacuum relief valve with pressure gauge and butterfly valve.

Racking arm.

Sample valve.

Top hop optional

| Product Paramenters

We have standard dimensions for beer fermentation tank for your quick choice, if you need other sizes please contact us, we design and custom free of charge for you.

Volume | Diameter | Height | ||

Internal Dia. | External Dia. | Shell H | Total H | |

2BBL | 600 | 720 | 810 | 1600 |

3BBL | 750 | 910 | 810 | 1800 |

5BBL | 900 | 1050 | 915 | 2000 |

7BBL | 950 | 1100 | 1220 | 2270 |

10BBL | 1050 | 1210 | 1400 | 3100 |

15BBL | 1250 | 1360 | 135 | 2400 |

20BBL | 1400 | 1560 | 1500 | 2650 |

30BBL | 1600 | 1760 | 1700 | 3100 |

40BBL | 1600 | 1760 | 2250 | 3545 |

60BBL | 2000 | 2200 | 2200 | 4915 |

90BBL | 2000 | 2160 | 3500 | 5050 |

120BBL | 2100 | 2260 | 4200 | 5700 |

We provide turnkey engineering services,contact us with market@prettech.cn

| Product Features

| Pressure control |

Beer fermenter is kind of pressurized tank with working pressure 0.1MPA-0.15MPA, and fitted with pressure controlling and display settings, such as vacuum pressure relief valve, CO2 discharging pipe and safety valve, release and keep the carbonation happened during fermenting. All Prettech beer fermentation tanks are tested by leakage proof before delivery, fittings and gaskets are strong, durable and sealed well, you will feel very happy and comfortable to use Prettech brewery tanks, make nice beer. |

| Sanitary processing |

The whole tanks are welded by 100% TIG, all welding seams are grounded and sanitary polished,burs removed, interior finish roughness less than 0.4um,exterior finish brushed polished.Top and bottom are welded onto the cylinder by Radian pressing, avoid any dead angle, easy to clean. |

| Excellent design and fabricate |

Pretank brewery tanks are heavy-duty made with high quality, the cutting and welding processing is made by laser machines, particularly for dimple jackets, it has a 0.35MPA working pressure supporting, the jacket covers on cylinder and conical,big cooling area and high efficiency for beer chilling. Beer ferment vessel is designed with PU foam as insulation material and SUS304 steel as cladding, reduce heat energy loss. |

| Control temperature accurately |

| Temperature needs to be controlled at varied stages during the whole of wort fermenting, Prettech consider this point and fit nice quality solenoid valve on the beer tanks to sensor the wort temperature inside of the beer tanks, and transmit the signal to controller. Pretty well temperature probe are used either. |

| Main Accessories

cleaning ball

cleaning ball  pressure relief valve

pressure relief valve  pressure valve

pressure valve  PT100

PT100

safety valve

| Customer Cases

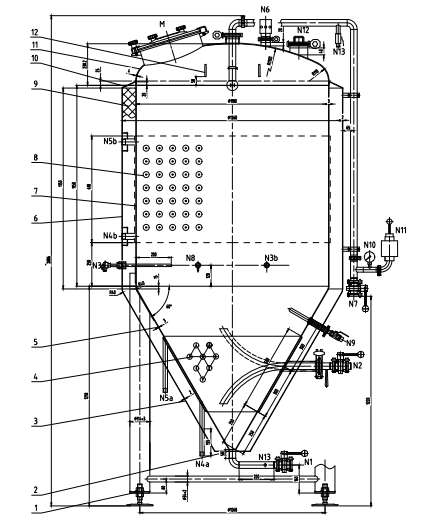

| Product Description

Wort is pumped into Beer fermentation tank for fermenting with the support of yeast and oxygen for 7-21 days at temperature between7℃~22℃,coolant would be used for cooling down the temperature,and pressure controlling devices are used for operating the beer fermenting tanks,sugar is converted to alcohol in Prettech beer fermenting tank(CCS).

Prettech construct the brewing fermenting tanks with high quality stainless steel 304 material, the shell is cylindrical, it has big conical angle on the bottom for easy exhaust and recycle yeast,dished top for better pressure bearing.

| Product Configuration

Material:SS304

Finish: Exterior brushed, interior polished<0.4um,welds grounded sanitary.

Head space: 25%.

Designing/working pressure: 0.2MPa, --0.1MPa.

Dished top, conical bottom 60 degree.

Dimple jacket on shell and bottom.

Glycol water inlet/outlet .

Insulation PU foam material 80mm thick and 2mm S/S cladding

4 legs with adjustable feet.

Elliptical manhole 450*350mm.

Outlet&drain port with tri clamp and butterfly valve.

Temperature probe PT100 and thermometer.

Solenoid valve.

Safety valve.

CIP ball and tubes with tri clamp and valve.

Pressure vacuum relief valve with pressure gauge and butterfly valve.

Racking arm.

Sample valve.

Top hop optional

| Product Paramenters

We have standard dimensions for beer fermentation tank for your quick choice, if you need other sizes please contact us, we design and custom free of charge for you.

Volume | Diameter | Height | ||

Internal Dia. | External Dia. | Shell H | Total H | |

2BBL | 600 | 720 | 810 | 1600 |

3BBL | 750 | 910 | 810 | 1800 |

5BBL | 900 | 1050 | 915 | 2000 |

7BBL | 950 | 1100 | 1220 | 2270 |

10BBL | 1050 | 1210 | 1400 | 3100 |

15BBL | 1250 | 1360 | 135 | 2400 |

20BBL | 1400 | 1560 | 1500 | 2650 |

30BBL | 1600 | 1760 | 1700 | 3100 |

40BBL | 1600 | 1760 | 2250 | 3545 |

60BBL | 2000 | 2200 | 2200 | 4915 |

90BBL | 2000 | 2160 | 3500 | 5050 |

120BBL | 2100 | 2260 | 4200 | 5700 |

We provide turnkey engineering services,contact us with market@prettech.cn

| Product Features

| Pressure control |

Beer fermenter is kind of pressurized tank with working pressure 0.1MPA-0.15MPA, and fitted with pressure controlling and display settings, such as vacuum pressure relief valve, CO2 discharging pipe and safety valve, release and keep the carbonation happened during fermenting. All Prettech beer fermentation tanks are tested by leakage proof before delivery, fittings and gaskets are strong, durable and sealed well, you will feel very happy and comfortable to use Prettech brewery tanks, make nice beer. |

| Sanitary processing |

The whole tanks are welded by 100% TIG, all welding seams are grounded and sanitary polished,burs removed, interior finish roughness less than 0.4um,exterior finish brushed polished.Top and bottom are welded onto the cylinder by Radian pressing, avoid any dead angle, easy to clean. |

| Excellent design and fabricate |

Pretank brewery tanks are heavy-duty made with high quality, the cutting and welding processing is made by laser machines, particularly for dimple jackets, it has a 0.35MPA working pressure supporting, the jacket covers on cylinder and conical,big cooling area and high efficiency for beer chilling. Beer ferment vessel is designed with PU foam as insulation material and SUS304 steel as cladding, reduce heat energy loss. |

| Control temperature accurately |

| Temperature needs to be controlled at varied stages during the whole of wort fermenting, Prettech consider this point and fit nice quality solenoid valve on the beer tanks to sensor the wort temperature inside of the beer tanks, and transmit the signal to controller. Pretty well temperature probe are used either. |

| Main Accessories

cleaning ball

cleaning ball  pressure relief valve

pressure relief valve  pressure valve

pressure valve  PT100

PT100

safety valve

| Customer Cases

About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

content is empty!