CHM-Top1

Prettech

500L-30,000L

| Availability: | |

|---|---|

| Product Description

Pretank can design and manufacture chemical blending tanks based on our customer's process conditions. These tanks are design with the tank standrad GB/T150.1~150.4-2011orASME BPVC Ⅷ-1 standard.Aigitator standard HG/T20569-2013.The equipment can be made of carbon steel, stainless steel and other materials according to the process requirements of the user's products, and set up heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. The equipment has reasonable structure design, advanced technology, durability, and has the characteristics of simple operation and convenient use.

Structure | Open top with hinged lids&Conical bottom ,support by legs or lifting lugs.Double wall with insulation. |

Materia | Material adopts S304 |

Jacket Type | Cooling jacket |

Insulation | 75mm insulation with 2mm cladding |

Surface Finishing | Internal &exterial :2B finish |

| Accessories | Manhole, Cooling jacket,agitator, thermometer, inlet /outlet, Drainage ,Air vent, Liquid level. |

Agitator | Tank according to GB/T150.1~150.4-2011 standard,Agitator meet HG/T20569-2013 standard. |

OEM/ODM | Can be customized according to customers requirement and product process. |

The chemical blending tanks capacity range from 500 liter to 50,000 liter,the specifications can be customized,please send your RFQ for more details. Meanwhile, associated with the stainless steel mixing tank,we also supply hot water tank, dissolving tank,alkali tank,vaccum buffer tank,sterilizing tank and CIP system.

Please inquire particular If you need any of them.

Tailor-made capacity ranging from 500L to 30000L, catering to your specific requirements.

Versatile material options including stainless steel 304 or 316, and even 316Tai, ensuring compatibility with various substances.

Diverse blending types available to accommodate different product processes effectively.

Incorporates a double jacket structure for efficient heat transfer and temperature control.

Robust and user-friendly design, allowing for easy operation and cleaning.

Inner tank wall features an arc transition in the transition area, eliminating any sanitary dead angles.

Convenient discharge options: direct bottom discharge or via a transfer pump.

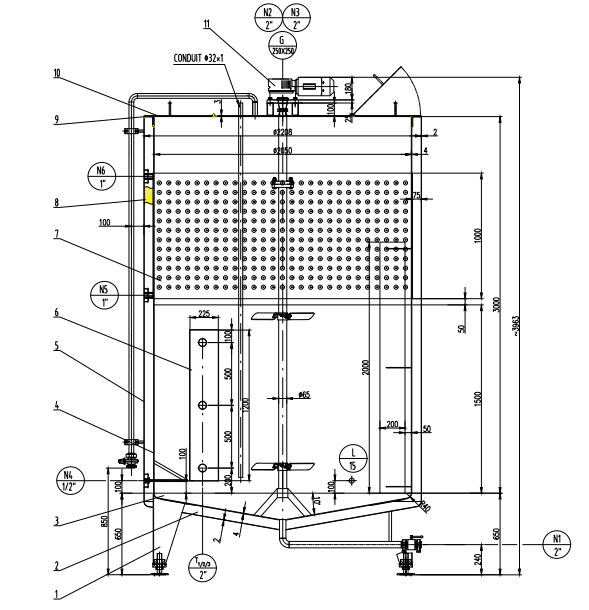

Pretank drawing of chemical blending tank are widely used in detergent,cosmetics,condiment,fertilizer,pigment etc industries.

Wrapped by blanket to aviod crash

Wooden protect to prevent agitator sway on the road

Load into container with saddle support and braced by steel strips

1. Except for SUS304 material, what other material do you do for the vessels?

A: We can provide a variety of grades of stainless steel, including SUS316L,SUS321,SUS316Ti; We also can make with material of titanium and Hastelloy Alloy.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3.How do you ship the goods?

Goods are usually shipped in containers or flat rack with metal walls to protect them against extreme temperatures and bad weather conditions.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5.What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

| Product Description

Pretank can design and manufacture chemical blending tanks based on our customer's process conditions. These tanks are design with the tank standrad GB/T150.1~150.4-2011orASME BPVC Ⅷ-1 standard.Aigitator standard HG/T20569-2013.The equipment can be made of carbon steel, stainless steel and other materials according to the process requirements of the user's products, and set up heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. The equipment has reasonable structure design, advanced technology, durability, and has the characteristics of simple operation and convenient use.

Structure | Open top with hinged lids&Conical bottom ,support by legs or lifting lugs.Double wall with insulation. |

Materia | Material adopts S304 |

Jacket Type | Cooling jacket |

Insulation | 75mm insulation with 2mm cladding |

Surface Finishing | Internal &exterial :2B finish |

| Accessories | Manhole, Cooling jacket,agitator, thermometer, inlet /outlet, Drainage ,Air vent, Liquid level. |

Agitator | Tank according to GB/T150.1~150.4-2011 standard,Agitator meet HG/T20569-2013 standard. |

OEM/ODM | Can be customized according to customers requirement and product process. |

The chemical blending tanks capacity range from 500 liter to 50,000 liter,the specifications can be customized,please send your RFQ for more details. Meanwhile, associated with the stainless steel mixing tank,we also supply hot water tank, dissolving tank,alkali tank,vaccum buffer tank,sterilizing tank and CIP system.

Please inquire particular If you need any of them.

Tailor-made capacity ranging from 500L to 30000L, catering to your specific requirements.

Versatile material options including stainless steel 304 or 316, and even 316Tai, ensuring compatibility with various substances.

Diverse blending types available to accommodate different product processes effectively.

Incorporates a double jacket structure for efficient heat transfer and temperature control.

Robust and user-friendly design, allowing for easy operation and cleaning.

Inner tank wall features an arc transition in the transition area, eliminating any sanitary dead angles.

Convenient discharge options: direct bottom discharge or via a transfer pump.

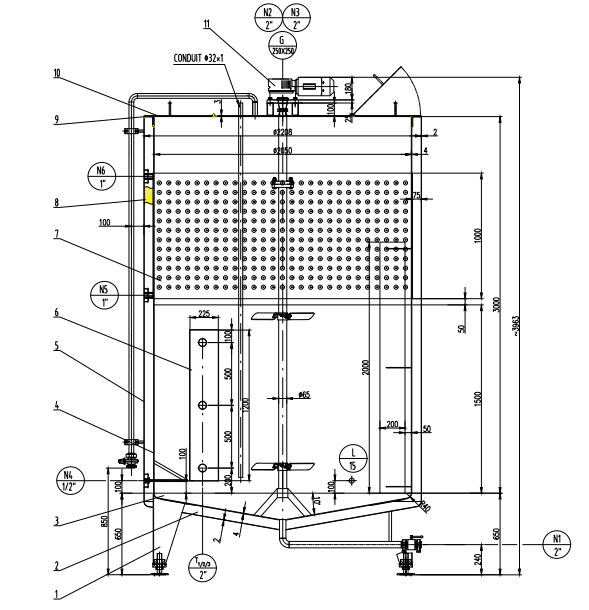

Pretank drawing of chemical blending tank are widely used in detergent,cosmetics,condiment,fertilizer,pigment etc industries.

Wrapped by blanket to aviod crash

Wooden protect to prevent agitator sway on the road

Load into container with saddle support and braced by steel strips

1. Except for SUS304 material, what other material do you do for the vessels?

A: We can provide a variety of grades of stainless steel, including SUS316L,SUS321,SUS316Ti; We also can make with material of titanium and Hastelloy Alloy.

2. We did not know how to do the import, could you help us to deliver the goods to our door?

A:Of course! We can do DDU or DAP terms. We can take care of the whole process from our factory to your door and you only need to make the unloading work within the specified time.

3.How do you ship the goods?

Goods are usually shipped in containers or flat rack with metal walls to protect them against extreme temperatures and bad weather conditions.

4. What should I do if there are quality problems?

A: We have a perfect quality control system to ensure there is no quality problem before dispatch. But in case there do have quality problem after arrival, we also have a rapid response and processing mechanism and reply in first time as we are 7 * 24 hours standby. Local repair as well as cargo replacement is supported to solve the problem.

5.What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

6. Can you produce according to my requirements or drawings?

A: Yes,we can. Actually we always custimze for our customers and each project will have a special drawing. The customize point can be material, dimension, accessories as well as orientation and so on.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

content is empty!